|

Sponsored by |

|---|

|

|

|

-

Need help navigating the forum? Find out how to use our features here.

-

Did you know we have lots of smilies for you to use?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Safety Eds TNT Woodscents Vaporizer

- Thread starter herbivore21

- Start date

herbivore21

Well-Known Member

removed pending further reading.

Last edited:

removed pending further reading.

Good evening sir, not sure I understand the removed pending. Maybe it's just me, if so forgive me.

herbivore21

Well-Known Member

No problem my friend, I had added a post but then realized I had some additional sources to parse and refer to in my post so removed for now. I am quite conscious that I need to add information as accurately as possible here and prefer not to leave something that may not quite reflect the nuance of the literature I am talking about :)Good evening sir, not sure I understand the removed pending. Maybe it's just me, if so forgive me.

herbivore21

Well-Known Member

I had to come back here to point out that when I first approved this vaporizer, I had unfortunately misunderstood a sentence from Ed and so failed to ask for crucial further testing to ensure that the teflon insulation on the wires does not get too hot during use.

I came away from reading Ed's last comment on the teflon insulation inaccurately thinking that the teflon insulation did not make contact with the heater. I do apologize for this. As such, I have undertaken to have Ed carry out further testing to ensure safety of the PTFE.

As many will know, PTFE when heated excessively outgasses harmful compounds such as PFOA, a carcinogenic compound with some frightening health impacts for humans and other animals. Despite my highlighting earlier in this thread that the most dangerous compounds are released from PTFE at temps much higher still, PTFE toxicity at lower temps than 572f have been observed by researchers to be caused by sublimation of a portion of the PTFE polymer with lower molecular weight.

At lower temps than those nastiest compounds are known to outgas, PTFE can sublimate and be inhaled, leaving small particulates of PTFE inside the user which can lead to pathology in humans and has even caused death in a variety lab/agricultural animals. It would be unsafe to overheat Teflon in a vaporizer air path.

For some general background on the dangers of PTFE: the lowest recorded temperature that I have found in the peer reviewed literature at which a thin coating of PTFE has been shown to kill birds is 396f. This was due to a non stick coating on new heat lamps in a bird pen. Half of the birds were dead within 3 days of exposure. Obviously, we only have animal studies for potentially lethal exposures like this. This thing called 'research ethics' prevents us from trying that with people!

Human beings may be more resilient to the same level of exposure that might kill small animals, sure. However, to be considered safe, we must be sure that the vaporizer in question cannot be shown to be able to heat the insulation enough to volatilize the teflon or any constituent therein at all. This means that there must be no evidence of temps around the teflon exceeding those recorded to have led to volatilization of PTFE in the research literature.

As always, @Ed's TnT has graciously provided some further testing of the unit for us.

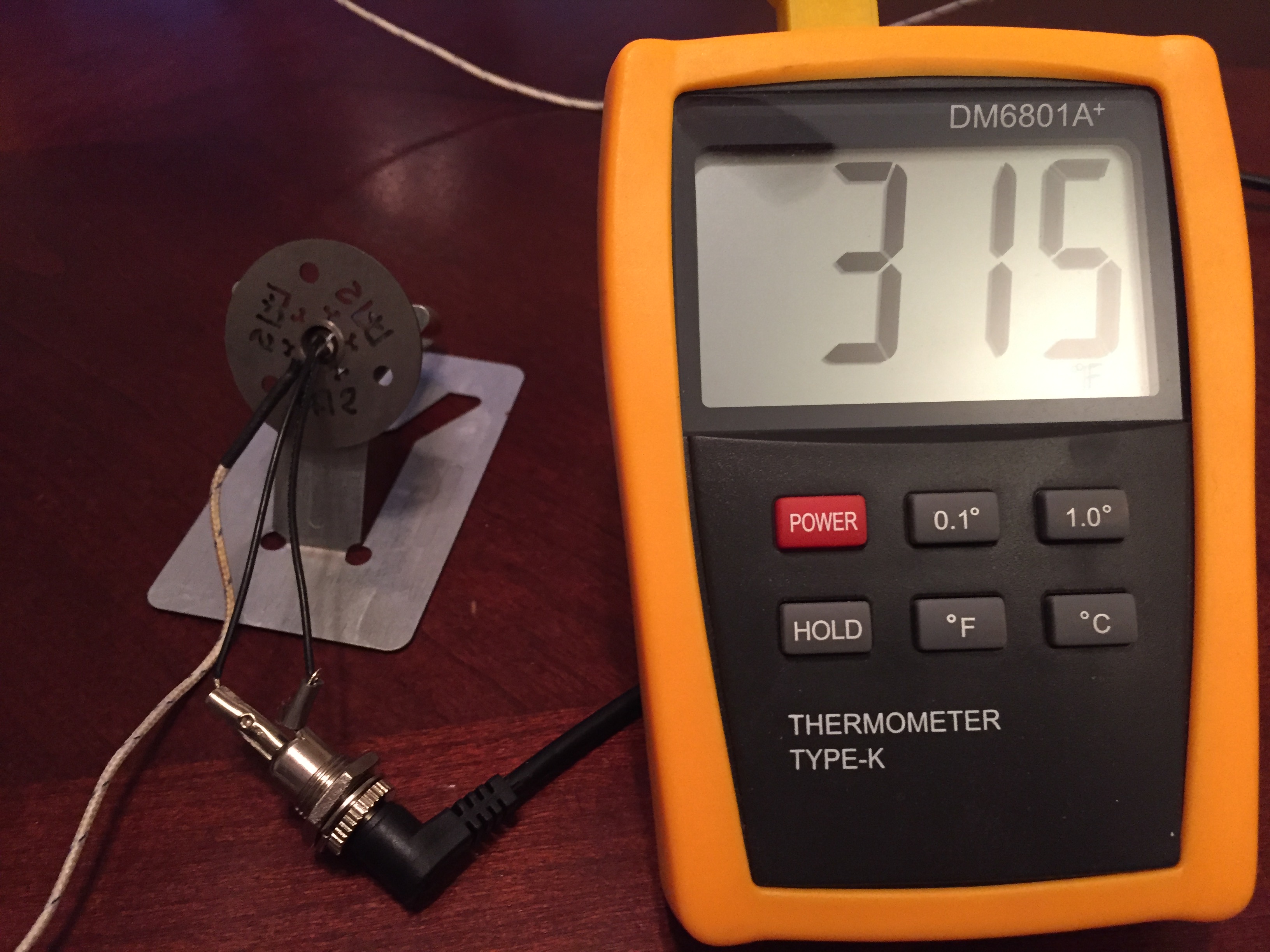

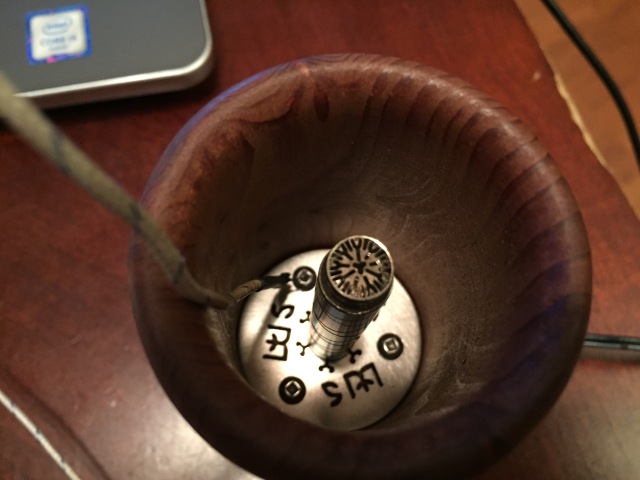

I requested that he turn the heater up to max temp, let the heat stabilize for an hour and then measure the temperature at the base of the heater, near the end of the teflon insulation where it meets the bottom of the heater. I have attached his own picture for reference (thanks to Ed for this pic!):

The temperature measured from the base of a fully heatsoaked heater at max temp for over an hour was 315f, as we can all see in the picture.

This is thankfully a lower temperature than we can find any peer reviewed evidence to scare us over. Moreover, we must consider that Ed instructs users never to use the maximum temperature and also that this max temp will combust your flower! We must also be mindful that we should expect temps during normal use (up to 8 or so on the dial) to be noteworthily less than what Ed measured above in our stress test, where the unit had run at max temp for an hour.

This means that even in unreasonable usage scenarios (like running a log at max temp!), let alone reasonable usage cases, there is no evidence that I have found to raise concern here.

I will, like Ed (see https://edstnt.com/woodscents-titan...-aromalog-frequently-asked-questions-eds-tnt/), make the following recommendations to prolong the life of your Woodscents log and further minimize any heat on the teflon insulation:

*Avoid operating your Woodscents without a VVPS or at max voltage, ever. While this is what we tested above, you will all appreciate that this sort of temp is counter-productive for vaporization (ie: will cause combustion). It will also increase stress on all of the internal components, the teflon and even your wood (which may require butter/oil based treatment more frequently).

* Following Ed's recommendation not to leave the unit turned on for long periods is advised.

* Avoid leaving your Woodscents inverted while the heater is on for long periods. A long rip upside down on your rig is not something to worry about, but anything longer should be avoided. Long periods of inversion at high temps would be likely to concentrate more heat at the base of the heater than otherwise would find its way there. These are the same instructions given by the manufacturers of the EVO; as many of you know.

I am glad to say that even with this further testing, Ed's Woodscents can still be said to be reasonably safe for use and retain a safety approval.

I thank Ed for his ongoing and gracious participation. It has been truly appreciated!

I came away from reading Ed's last comment on the teflon insulation inaccurately thinking that the teflon insulation did not make contact with the heater. I do apologize for this. As such, I have undertaken to have Ed carry out further testing to ensure safety of the PTFE.

As many will know, PTFE when heated excessively outgasses harmful compounds such as PFOA, a carcinogenic compound with some frightening health impacts for humans and other animals. Despite my highlighting earlier in this thread that the most dangerous compounds are released from PTFE at temps much higher still, PTFE toxicity at lower temps than 572f have been observed by researchers to be caused by sublimation of a portion of the PTFE polymer with lower molecular weight.

At lower temps than those nastiest compounds are known to outgas, PTFE can sublimate and be inhaled, leaving small particulates of PTFE inside the user which can lead to pathology in humans and has even caused death in a variety lab/agricultural animals. It would be unsafe to overheat Teflon in a vaporizer air path.

For some general background on the dangers of PTFE: the lowest recorded temperature that I have found in the peer reviewed literature at which a thin coating of PTFE has been shown to kill birds is 396f. This was due to a non stick coating on new heat lamps in a bird pen. Half of the birds were dead within 3 days of exposure. Obviously, we only have animal studies for potentially lethal exposures like this. This thing called 'research ethics' prevents us from trying that with people!

Human beings may be more resilient to the same level of exposure that might kill small animals, sure. However, to be considered safe, we must be sure that the vaporizer in question cannot be shown to be able to heat the insulation enough to volatilize the teflon or any constituent therein at all. This means that there must be no evidence of temps around the teflon exceeding those recorded to have led to volatilization of PTFE in the research literature.

As always, @Ed's TnT has graciously provided some further testing of the unit for us.

I requested that he turn the heater up to max temp, let the heat stabilize for an hour and then measure the temperature at the base of the heater, near the end of the teflon insulation where it meets the bottom of the heater. I have attached his own picture for reference (thanks to Ed for this pic!):

The temperature measured from the base of a fully heatsoaked heater at max temp for over an hour was 315f, as we can all see in the picture.

This is thankfully a lower temperature than we can find any peer reviewed evidence to scare us over. Moreover, we must consider that Ed instructs users never to use the maximum temperature and also that this max temp will combust your flower! We must also be mindful that we should expect temps during normal use (up to 8 or so on the dial) to be noteworthily less than what Ed measured above in our stress test, where the unit had run at max temp for an hour.

This means that even in unreasonable usage scenarios (like running a log at max temp!), let alone reasonable usage cases, there is no evidence that I have found to raise concern here.

I will, like Ed (see https://edstnt.com/woodscents-titan...-aromalog-frequently-asked-questions-eds-tnt/), make the following recommendations to prolong the life of your Woodscents log and further minimize any heat on the teflon insulation:

*Avoid operating your Woodscents without a VVPS or at max voltage, ever. While this is what we tested above, you will all appreciate that this sort of temp is counter-productive for vaporization (ie: will cause combustion). It will also increase stress on all of the internal components, the teflon and even your wood (which may require butter/oil based treatment more frequently).

* Following Ed's recommendation not to leave the unit turned on for long periods is advised.

* Avoid leaving your Woodscents inverted while the heater is on for long periods. A long rip upside down on your rig is not something to worry about, but anything longer should be avoided. Long periods of inversion at high temps would be likely to concentrate more heat at the base of the heater than otherwise would find its way there. These are the same instructions given by the manufacturers of the EVO; as many of you know.

I am glad to say that even with this further testing, Ed's Woodscents can still be said to be reasonably safe for use and retain a safety approval.

I thank Ed for his ongoing and gracious participation. It has been truly appreciated!

andreaerdna

New Member

Wow, @herbivore21 you are really not doing this lightly! I didn't doubt about Ed's doing it right but is nice to see this be confirmed by serious testing!

I can see not a lot of vapes passing this safety screening (unfortunately)

Keep on!

I can see not a lot of vapes passing this safety screening (unfortunately)

Keep on!

herbivore21

Well-Known Member

Thank you kindly for the supportWow, @herbivore21 you are really not doing this lightly! I didn't doubt about Ed's doing it right but is nice to see this be confirmed by serious testing!

I can see not a lot of vapes passing this safety screening (unfortunately)

Keep on!

Good morning @herbivore21 Wow thanks so much for all you do as I have said several times, you have had a lot to go over to ensure that the WS passes and am glad to have made the cut, this is good news and am happy that you are happy and thats what its all about! I have made the changes to the FAQ so all is good and appropriate as it should be!

@andreaerdna Ill second that!

@andreaerdna Ill second that!

herbivore21

Well-Known Member

In follow up to this post, I have received feedback that disputed the testing quoted above, arguing that because the measurements of temps were taken from the heater outside of the unit, that temps inside the base cavity when the unit is assembled may be hotter and hence still pose a danger. I must point out that the dispute came from a direct competitor, and that whilst we have investigated the contentions raised, we have also introduced a new policy regarding sustained criticisms of vaporizers that originate from competitors (I quote @momofthegoons here, see: https://vaporasylum.com/threads/vaporizer-safety-approval.183/ ):I had to come back here to point out that when I first approved this vaporizer, I had unfortunately misunderstood a sentence from Ed and so failed to ask for crucial further testing to ensure that the teflon insulation on the wires does not get too hot during use.

I came away from reading Ed's last comment on the teflon insulation inaccurately thinking that the teflon insulation did not make contact with the heater. I do apologize for this. As such, I have undertaken to have Ed carry out further testing to ensure safety of the PTFE.

As many will know, PTFE when heated excessively outgasses harmful compounds such as PFOA, a carcinogenic compound with some frightening health impacts for humans and other animals. Despite my highlighting earlier in this thread that the most dangerous compounds are released from PTFE at temps much higher still, PTFE toxicity at lower temps than 572f have been observed by researchers to be caused by sublimation of a portion of the PTFE polymer with lower molecular weight.

At lower temps than those nastiest compounds are known to outgas, PTFE can sublimate and be inhaled, leaving small particulates of PTFE inside the user which can lead to pathology in humans and has even caused death in a variety lab/agricultural animals. It would be unsafe to overheat Teflon in a vaporizer air path.

For some general background on the dangers of PTFE: the lowest recorded temperature that I have found in the peer reviewed literature at which a thin coating of PTFE has been shown to kill birds is 396f. This was due to a non stick coating on new heat lamps in a bird pen. Half of the birds were dead within 3 days of exposure. Obviously, we only have animal studies for potentially lethal exposures like this. This thing called 'research ethics' prevents us from trying that with people!

Human beings may be more resilient to the same level of exposure that might kill small animals, sure. However, to be considered safe, we must be sure that the vaporizer in question cannot be shown to be able to heat the insulation enough to volatilize the teflon or any constituent therein at all. This means that there must be no evidence of temps around the teflon exceeding those recorded to have led to volatilization of PTFE in the research literature.

As always, @Ed's TnT has graciously provided some further testing of the unit for us.

I requested that he turn the heater up to max temp, let the heat stabilize for an hour and then measure the temperature at the base of the heater, near the end of the teflon insulation where it meets the bottom of the heater. I have attached his own picture for reference (thanks to Ed for this pic!):

The temperature measured from the base of a fully heatsoaked heater at max temp for over an hour was 315f, as we can all see in the picture.

This is thankfully a lower temperature than we can find any peer reviewed evidence to scare us over. Moreover, we must consider that Ed instructs users never to use the maximum temperature and also that this max temp will combust your flower! We must also be mindful that we should expect temps during normal use (up to 8 or so on the dial) to be noteworthily less than what Ed measured above in our stress test, where the unit had run at max temp for an hour.

This means that even in unreasonable usage scenarios (like running a log at max temp!), let alone reasonable usage cases, there is no evidence that I have found to raise concern here.

I will, like Ed (see https://edstnt.com/woodscents-titan...-aromalog-frequently-asked-questions-eds-tnt/), make the following recommendations to prolong the life of your Woodscents log and further minimize any heat on the teflon insulation:

*Avoid operating your Woodscents without a VVPS or at max voltage, ever. While this is what we tested above, you will all appreciate that this sort of temp is counter-productive for vaporization (ie: will cause combustion). It will also increase stress on all of the internal components, the teflon and even your wood (which may require butter/oil based treatment more frequently).

* Following Ed's recommendation not to leave the unit turned on for long periods is advised.

* Avoid leaving your Woodscents inverted while the heater is on for long periods. A long rip upside down on your rig is not something to worry about, but anything longer should be avoided. Long periods of inversion at high temps would be likely to concentrate more heat at the base of the heater than otherwise would find its way there. These are the same instructions given by the manufacturers of the EVO; as many of you know.

I am glad to say that even with this further testing, Ed's Woodscents can still be said to be reasonably safe for use and retain a safety approval.

I thank Ed for his ongoing and gracious participation. It has been truly appreciated!

"While we encourage communication from all manufacturers, negative correspondence from one vendor regarding another vendor's product is a conflict of interest and if sustained, will be considered company bashing."

I will add personally that while I appreciate and respect that direct competitors who manufacture similar products may have relevant design and safety knowledge to contribute, that we must also not discount the very obvious conflict of interest that comes when somebody who makes something for a living criticizes a very similar product made by somebody else in the same market. Nonetheless, I've taken the time to investigate the concerns raised.

Thankfully, Ed has helped us out again with more gracious temp measurements. This will be the final update to this thread.

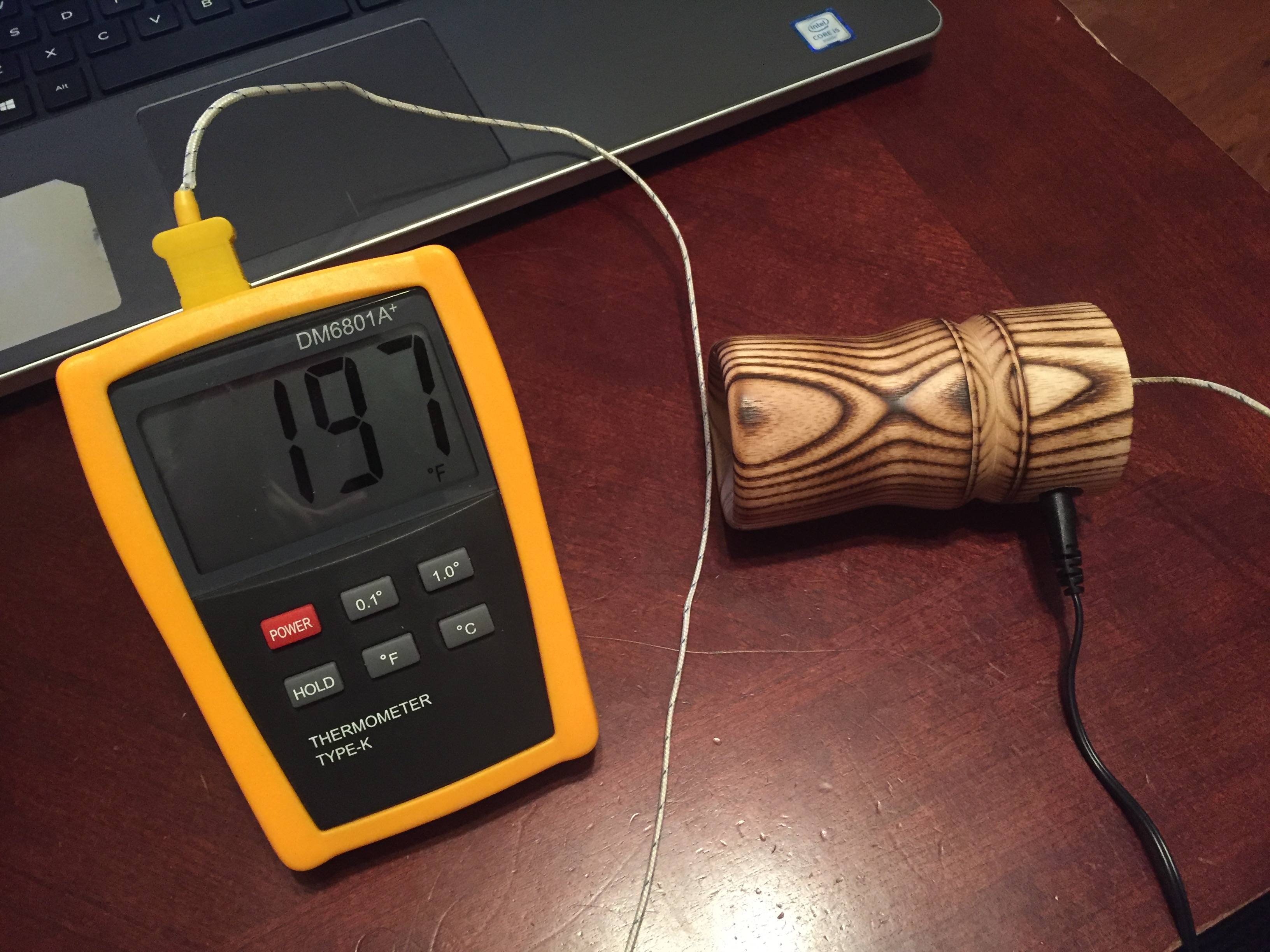

I asked Ed to measure temps in the cavity underneath the heater when installed in the wooden enclosure. I requested that prior to measurement, that he should leave the unit on at max temp (no dimmer installed, full 12v power) for one hour before measurement. As we can see here, he kindly obliged:

The temp measured in this case did not even meet the boiling point of water. This is not even close to a temperature that has ever been shown to be risky for teflon sublimation.

Ed also tested the temp from the top of the unit while running at max temp for over an hour:

Again, this temp is not even close to anything that has been shown to lead to sublimation/offgassing of PTFE.

Ed also measured from the top of the screws, which barely get hotter than boiling water:

There was also mention that the cotton plug used may be exposed to excessive heat, so I had Ed test the temps during max temp operation after 1 hour to see how hot the cotton would get:

As we can see, the temp recorded does not even reach the boiling point of water. Needless to say, this is not a dangerous temp to expose the cotton to. If this were dangerous, all of those who use cotton as a screen to vape concentrates would need to abandon this practice in an uncomfortable hurry (with that said, I recommend SS mesh over cotton wool for dabs in any case)!

Whilst I did request a measurement with the thermocouple placed inside the y shaped cutouts closest to the heater tube itself, unfortunately, the thermocouple was too big to fit.

However, after this most recent battery of testing, it remains that we have not observed any temps from any of the now very numerous temp measurements taken from the unit in various states of assembly, both inverted and upright. When we consider that all testing was done at max temp, and that Ed never recommends use at max temp, this product remains safe with regard to the contentions raised above.

Last edited:

Thankfully, Ed has helped us out again with more gracious temp measurements. This will be the final update to this thread.

However, after this most recent battery of testing, it remains that we have not observed any temps from any of the now very numerous temp measurements taken from the unit in various states of assembly, both inverted and upright. When we consider that all testing was done at max temp, and that Ed never recommends use at max temp, this product remains safe with regard to the contentions raised above.

Hello and good morning, gosh thanks for all the updates here bro, I am most grateful and thank you for pointing out to all that the WoodScents performs in a safe manner. Thats what its all about and now there is no disputing it. Thanks for all the time you put into this matter and for the time you donate here at VA. You are very much appreciated, thank you!

A lot of work gone into all this, figures speak for themselves @Ed's TnT.

If there's no doubts in @herbivore21's mind then surely there can be no doubts in anyone else's mind.

If there's no doubts in @herbivore21's mind then surely there can be no doubts in anyone else's mind.

GreenHopper

20 going on 60

Agreed, thank you @herbivore21 and @Ed's TnT for taking the time and making the effort to provide such a wealth of transparency and assurance.

Very much appreciated!

Very much appreciated!

herbivore21

Well-Known Member

You're too kind my friend. Thank you!A lot of work gone into all this, figures speak for themselves @Ed's TnT.

If there's no doubts in @herbivore21's mind then surely there can be no doubts in anyone else's mind.

Thanks man, more than anything, I want to provide transparency in the process hereAgreed, thank you @herbivore21 and @Ed's TnT for taking the time and making the effort to provide such a wealth of transparency and assurance.

Very much appreciated!

If nothing else, I hope anybody who does not take my word for it can look at the measurements here independent of my own rationale and decide for themselves what they think is safe or not

I'm glad my friend. Thanks so much for working with us on this one. I appreciate that you did a lot of back and forth on the measurements after having been told we were done looking once or twice. I do apologize for any of your time that was wasted in making sure we did this thoroughly.Hello and good morning, gosh thanks for all the updates here bro, I am most grateful and thank you for pointing out to all that the WoodScents performs in a safe manner. Thats what its all about and now there is no disputing it. Thanks for all the time you put into this matter and for the time you donate here at VA. You are very much appreciated, thank you!

You've been very diligent! I'm glad that people here appear to be seeing your dedication and effort here and rewarding that with their patronage. Well earned, in my view! Thanks again

7heLameGuy

New Member

@Ed’s TnT

I was looking to buy your vaporizer, i noticed it has a cartridge heater sheathed with stainless steel.

What kind of heating coil is used inside the cartridge? The most common type of metal alloy used for this purpose is a nickel-chromium mixture, also known as nichrome. The nichrome wire is wound around a ceramic core, and the number of spirals per inch depend on it’s watt density. Does your heater cartridge use a similar design that utilizes nickel-chromium? And is the ceramic used vitrified ceramic?

I was looking to buy your vaporizer, i noticed it has a cartridge heater sheathed with stainless steel.

What kind of heating coil is used inside the cartridge? The most common type of metal alloy used for this purpose is a nickel-chromium mixture, also known as nichrome. The nichrome wire is wound around a ceramic core, and the number of spirals per inch depend on it’s watt density. Does your heater cartridge use a similar design that utilizes nickel-chromium? And is the ceramic used vitrified ceramic?

7heLameGuy

New Member

I contacted underdog log vapes which use a similar cartridge heater assembly as woodscents, they told me “Thanks for getting in touch. Yes, our cartridges are custom made for us and have a nichrome coil wound in ceramic with an external stainless sheath, just as you described.”

There is no way nichel-chromium alloy can be safe in air path, even if covered with steel, the particulate matter from the nichome would escape from any openings it sees in the sheathing.

There is no way nichel-chromium alloy can be safe in air path, even if covered with steel, the particulate matter from the nichome would escape from any openings it sees in the sheathing.

@7heLameGuy Several log vapes use this type of ceramic heater. And nichrome wire is used extensively in coils made for wax pens and in e-cigs. And used in toasters and hair dryers (that blow air). So saying that there "is no way this is safe" is a sweeping statement made without substantiation.

However, now that you have raised the question, we will look into this further and get back to you within a couple days with substantiation of it's safety.

However, now that you have raised the question, we will look into this further and get back to you within a couple days with substantiation of it's safety.

A quick Google search got me quite a bit of information regarding how any "particulate matter" would be formed. What I gathered from this fact sheet on resistance wire is:

The nichrome would have to oxidize, rust or corrode. Since nichrome is a resistance wire it does not do this easily "even under extreme conditions" (as per the fact sheet). The application we are discussing is in a vaporizer that is, most likely, not going to be exposed to extreme conditions. It will, however, be exposed to continuous heat. According to the fact sheet, nichrome, which in this case is encased in stainless steel, must reach a temperature of over 1150° C (2100° F) to melt.

This vaporizer does not come anywhere near those temperatures.

So I am not sure how you feel that the nichrome will form any type of particulate that would be hazardous in this application.

The nichrome would have to oxidize, rust or corrode. Since nichrome is a resistance wire it does not do this easily "even under extreme conditions" (as per the fact sheet). The application we are discussing is in a vaporizer that is, most likely, not going to be exposed to extreme conditions. It will, however, be exposed to continuous heat. According to the fact sheet, nichrome, which in this case is encased in stainless steel, must reach a temperature of over 1150° C (2100° F) to melt.

This vaporizer does not come anywhere near those temperatures.

So I am not sure how you feel that the nichrome will form any type of particulate that would be hazardous in this application.

herbivore21

Well-Known Member

What stands out to me here is that nobody anywhere in this thread has said that the Woodscents uses a nichrome coil inside the cartridge heater in the first place. This discussion seems to revolve around a straw man!So I am not sure how you feel that the nichrome will form any type of particulate that would be hazardous in this application.

Perhaps @Ed's TnT could help us out with information on what the heater cartridge actually is made up of?

Good morning, forgive me @herbivore21 yesterday was a slammed day then when it got dark I wasnt to far from putting my head on the pillow. My days start at 4am for the most part, so much that needs done. I dont know why I didnt see any of these posts yesterday. It says I am watching this thread but havent gotten any notices.

TBH I never even thought to mention nichrome wire, its everywhere in everything we use. I spoke to my manufacturer and he told me that his company has been making these for better than 50 years going in all kinds of circumstances with never an issue with nichrome wire. Other log vape manufacturers use similar heater cartridges and all use nichrome wire. The wire is wrapped and set in the core then sheathed with SS. There is no issue with this.

As MOTG posted above, nichrome wire is in your toaster oven, its in a hair dryer.

On another note, I have changed the heater leads a bit so they are straight wire and wire alone. Have been doing them this way since the last batch came in and have just been so busy I havent posted up. Pls have a look below

Using glass beads to insulate the leads. Pulled this trick out of someone elses pocket haha hope ya like it!!! My man if there is anything you need from me pls pls let me know and I will get you the answers you need. You know I am always up for making it happen, just let me know how!

TBH I never even thought to mention nichrome wire, its everywhere in everything we use. I spoke to my manufacturer and he told me that his company has been making these for better than 50 years going in all kinds of circumstances with never an issue with nichrome wire. Other log vape manufacturers use similar heater cartridges and all use nichrome wire. The wire is wrapped and set in the core then sheathed with SS. There is no issue with this.

As MOTG posted above, nichrome wire is in your toaster oven, its in a hair dryer.

On another note, I have changed the heater leads a bit so they are straight wire and wire alone. Have been doing them this way since the last batch came in and have just been so busy I havent posted up. Pls have a look below

Using glass beads to insulate the leads. Pulled this trick out of someone elses pocket haha hope ya like it!!! My man if there is anything you need from me pls pls let me know and I will get you the answers you need. You know I am always up for making it happen, just let me know how!

herbivore21

Well-Known Member

@Ed's TnT : Thank you kindly for your response and update here sir! Also for your gracious participation!

I have had the opportunity to review the heater in question in more detail and thought I'd go through the materials one by one and review some safety considerations.

I have been provided with information from the heater component manufacturer to verification purposes (thank you for your cooperation, Ed!), which has been helpful here. I cannot divulge the particulars of Ed's heater manufacturer here for obvious reasons! However, below are my findings about the construction of the heater:

The heater in question is a stainless steel cartridge heater, comprising nichrome resistance wire wrapped around a magnesium oxide core.

The stainless steel is rated by the component manufacturer (not Ed!) to be safe to 1500f. Stainless steel is something that we are all used to accepting as safe in our vaporizers and probably not the material that readers are most interested in hearing about here, so we'll address the other materials.

It is worth taking a moment to consider the magnesium oxide used in this device:

Magnesium oxide may be known by many of you as 'magnesia'. This product is frequently used for human consumption in medical applications, such as for the treatment of GERD (reflux/indigestion related conditions). However, many of us are aware that not everything that is safe to eat, is safe to heat and inhale off of! So let's consider magnesia in a more application-specific way.

For our purposes, magnesium oxide as a material in an electronic component like a heater, provides high dielectric strength (a property that describes how well the material resists breaking down from exposure to electric fields). Magnesium oxide does not reach its melting point until ~5117f, meaning that if the heater were getting hot enough to cause this stuff to substantially deform, the stainless around the outside should also be visibly overheating and deforming.

In the scholarly literature, one consideration relating to safety of magnesium oxide has appeared. It relates to a potential relationship between heating of magnesium oxide resulting in Metal Fume Fever, an illness related to exposure of the gases/aerosols released from heated metals.

However, more recent reviews of the literature (such as this one: http://oeh.tandfonline.com/doi/abs/10.1080/15298660008984594), highlight: "Magnesium oxide, for example, often is cited as a metal for which there is

strong evidence of related MFF, but that evidence is actually equivocal. In a classic early experiment, exposure to freshly formed magnesium oxide induced MFF in one of four subjects, (42) but a recent experiment could not replicate that effect. (43)"

Before I go on to explain why MFF is not a concern; even if for some unfathomable reason, the Woodscents operated at temps high enough to volatilize Magnesium oxide (IT DOES NOT), let me explain why Magnesium Oxide should not be a cause of concern here:

Source (42) cited in the review is a 1927 article from an Indian journal, which considered only 4 subjects (this is a tiny study, and could only really be considered as a pilot, or case study due to the small sample size - it has no extrapolative validity).

The fact that source (43) could not replicate any such effects when that study was carried out later in the 1990's suggests, as per the source I cite above, that there is insufficient evidence to suggest any causal link Magnesium Oxide with MFF. In any case, the temps required to volatilize magnesium oxide, given its melting and boiling points, would be far beyond the max 650f temp in Ed's log.

Now we need to consider the final component inside the heater: Nichrome.

As Ed says, we almost all use nichrome based heat sources in our homes. If any of you have ever used a hair dryer, you're likely to have been having forced are blown over hot nichrome directed at your head every time you did so.

However, that is not to assume that everything in our houses is safe! We can all point to cases of dangerous shit that was once widely used and seen as a harmless household item!

So let's consider the properties of Nichrome:

Nichrome alloys generally have a melting point of between 2462f-~2700f or so. The closer we get to those temps, and depending on local variables such as barometric pressure etc, we would expect to see melting and deformation, as temps increase beyond that point, we would expect to start seeing outgassing and sublimation as temps approached the boiling point of the Nichrome alloy.

All of that is taken with a big pinch of salt of course: Given that and the max temp of the woodscents measured from the bottom of the heater is ~650f (we must of course consider that Ed's temp measurements are not taken from inside the heater, where the nichrome is, which would be expected to be somewhat hotter), we should not expect the nichrome to be experiencing problematic temps for volatilization/offgassing concerns.

We should also consider oxidation here: In addition nichrome being renowned for high resistance to high temp oxidation (google it), this nickel should be expected to suffer less from oxidation than the abovementioned ecig and e-nail coil heater examples mentioned, given that the nichrome is encased in an SS sheathe precisely to minimize the relevant oxygen exposure.

Moreover, the stainless sheath around the heater is according to the component manufacturer (Not Ed!), designed to tightly enclose the nichrome/magnesium oxide components to prevent oxidation where the resistance wire in the element is exposed to oxygen from the surrounding atmosphere. This should mean that the nichrome inside should stand up to higher temps even than those exposed nichrome coils that many of us regularly use in ecigs atomizers/dab pens/e-nail heaters. The heaters in question are according to the heater manufacturer (again, not Ed!) designed for use in contexts with large amounts of mechanical vibration that necessitates the very tight tolerances required for the density of the magnesium oxide, the wrapping of the resistive wire and the fit of the stainless sheath.

I cannot find any scholarly studies that specifically consider if there are any measurable concentrations of volatilized elements coming out of this kind of SS cartridge heater during use (however, some exist in relation to certain ecig heating wires, which are low, but may lead to problematic exposure in heavy ecig usage scenarios - this is not a comparable scenario, as in these cases, the resistive wire is directly in contact not only with the substance being vaporized, but also air from the surrounding atmosphere). In short, on the information I've found, I have no cause to believe that the nichrome used in this heater would be unsafe in the ways you suggest or otherwise.

I have however, found some information to suggest that we might not wanna inhale a lot off of exposed nichrome coils, like those used in some dab pens and ecigs (the study in question only looked at certain ecig designs however, so we should be careful before trying to extrapolate to all dab pens some of which can function differently where the abovementioned risk factors are concerned, see http://journals.plos.org/plosone/article?id=10.1371/journal.pone.0057987). As many of you know, I have not recommended pens for a long time now!

The manufacturer in question (Not Ed) designed this sheathe explicitly for the purpose of preventing oxidation/corrosion from the surrounding atmosphere (this means that the sheathe needs to prevent air from getting inside of the sheathe - air as you know, is rather more able to squeeze through the tightest of spaces than even volatilized particulates from nickel-chromium). If there were an opening in the sheathing, it would seem that this would utterly defeat that explicit purpose of the design of the component and would serve as quite the indictment of the manufacturer! I've seen no evidence to suggest that such a failure would take place, or ever has taken place.

@7heLameGuy In order to substantiate the initial cause of your concern, I need to ask: What makes you think that the stainless steel will have an 'opening' which exposes the nichrome within? Have you seen some evidence that made you concerned that this would happen?

I have at present seen nothing to suggest that such an opening, exposing the nichrome to the vapor path is present, neither in the pics from Ed, nor in the materials that I've seen from the component manufacturer?!

I do apologize, I don't have time to look at the new wiring in the bottom of the woodscents that Ed has shared as of yet due to pressing IRL engagements, however, I'll return once I get the chance to speak to this

I have had the opportunity to review the heater in question in more detail and thought I'd go through the materials one by one and review some safety considerations.

I have been provided with information from the heater component manufacturer to verification purposes (thank you for your cooperation, Ed!), which has been helpful here. I cannot divulge the particulars of Ed's heater manufacturer here for obvious reasons! However, below are my findings about the construction of the heater:

The heater in question is a stainless steel cartridge heater, comprising nichrome resistance wire wrapped around a magnesium oxide core.

The stainless steel is rated by the component manufacturer (not Ed!) to be safe to 1500f. Stainless steel is something that we are all used to accepting as safe in our vaporizers and probably not the material that readers are most interested in hearing about here, so we'll address the other materials.

It is worth taking a moment to consider the magnesium oxide used in this device:

Magnesium oxide may be known by many of you as 'magnesia'. This product is frequently used for human consumption in medical applications, such as for the treatment of GERD (reflux/indigestion related conditions). However, many of us are aware that not everything that is safe to eat, is safe to heat and inhale off of! So let's consider magnesia in a more application-specific way.

For our purposes, magnesium oxide as a material in an electronic component like a heater, provides high dielectric strength (a property that describes how well the material resists breaking down from exposure to electric fields). Magnesium oxide does not reach its melting point until ~5117f, meaning that if the heater were getting hot enough to cause this stuff to substantially deform, the stainless around the outside should also be visibly overheating and deforming.

In the scholarly literature, one consideration relating to safety of magnesium oxide has appeared. It relates to a potential relationship between heating of magnesium oxide resulting in Metal Fume Fever, an illness related to exposure of the gases/aerosols released from heated metals.

However, more recent reviews of the literature (such as this one: http://oeh.tandfonline.com/doi/abs/10.1080/15298660008984594), highlight: "Magnesium oxide, for example, often is cited as a metal for which there is

strong evidence of related MFF, but that evidence is actually equivocal. In a classic early experiment, exposure to freshly formed magnesium oxide induced MFF in one of four subjects, (42) but a recent experiment could not replicate that effect. (43)"

Before I go on to explain why MFF is not a concern; even if for some unfathomable reason, the Woodscents operated at temps high enough to volatilize Magnesium oxide (IT DOES NOT), let me explain why Magnesium Oxide should not be a cause of concern here:

Source (42) cited in the review is a 1927 article from an Indian journal, which considered only 4 subjects (this is a tiny study, and could only really be considered as a pilot, or case study due to the small sample size - it has no extrapolative validity).

The fact that source (43) could not replicate any such effects when that study was carried out later in the 1990's suggests, as per the source I cite above, that there is insufficient evidence to suggest any causal link Magnesium Oxide with MFF. In any case, the temps required to volatilize magnesium oxide, given its melting and boiling points, would be far beyond the max 650f temp in Ed's log.

Now we need to consider the final component inside the heater: Nichrome.

As Ed says, we almost all use nichrome based heat sources in our homes. If any of you have ever used a hair dryer, you're likely to have been having forced are blown over hot nichrome directed at your head every time you did so.

However, that is not to assume that everything in our houses is safe! We can all point to cases of dangerous shit that was once widely used and seen as a harmless household item!

So let's consider the properties of Nichrome:

Nichrome alloys generally have a melting point of between 2462f-~2700f or so. The closer we get to those temps, and depending on local variables such as barometric pressure etc, we would expect to see melting and deformation, as temps increase beyond that point, we would expect to start seeing outgassing and sublimation as temps approached the boiling point of the Nichrome alloy.

All of that is taken with a big pinch of salt of course: Given that and the max temp of the woodscents measured from the bottom of the heater is ~650f (we must of course consider that Ed's temp measurements are not taken from inside the heater, where the nichrome is, which would be expected to be somewhat hotter), we should not expect the nichrome to be experiencing problematic temps for volatilization/offgassing concerns.

We should also consider oxidation here: In addition nichrome being renowned for high resistance to high temp oxidation (google it), this nickel should be expected to suffer less from oxidation than the abovementioned ecig and e-nail coil heater examples mentioned, given that the nichrome is encased in an SS sheathe precisely to minimize the relevant oxygen exposure.

Moreover, the stainless sheath around the heater is according to the component manufacturer (Not Ed!), designed to tightly enclose the nichrome/magnesium oxide components to prevent oxidation where the resistance wire in the element is exposed to oxygen from the surrounding atmosphere. This should mean that the nichrome inside should stand up to higher temps even than those exposed nichrome coils that many of us regularly use in ecigs atomizers/dab pens/e-nail heaters. The heaters in question are according to the heater manufacturer (again, not Ed!) designed for use in contexts with large amounts of mechanical vibration that necessitates the very tight tolerances required for the density of the magnesium oxide, the wrapping of the resistive wire and the fit of the stainless sheath.

I cannot find any scholarly studies that specifically consider if there are any measurable concentrations of volatilized elements coming out of this kind of SS cartridge heater during use (however, some exist in relation to certain ecig heating wires, which are low, but may lead to problematic exposure in heavy ecig usage scenarios - this is not a comparable scenario, as in these cases, the resistive wire is directly in contact not only with the substance being vaporized, but also air from the surrounding atmosphere). In short, on the information I've found, I have no cause to believe that the nichrome used in this heater would be unsafe in the ways you suggest or otherwise.

I have however, found some information to suggest that we might not wanna inhale a lot off of exposed nichrome coils, like those used in some dab pens and ecigs (the study in question only looked at certain ecig designs however, so we should be careful before trying to extrapolate to all dab pens some of which can function differently where the abovementioned risk factors are concerned, see http://journals.plos.org/plosone/article?id=10.1371/journal.pone.0057987). As many of you know, I have not recommended pens for a long time now!

If this release/escape of nichrome particulates happened (and you've not yet suggested how this could take place) this would entail a major design failure on the part of the component manufacturer (not Ed!), who could then be accused of making false claims about their product. This heater is explicitly designed for use in circumstances where there is substantial vibration; vibration that might, if strong enough, be expected to loosen particulates of hot nickel. The additional tight tolerances of the magnesium oxide, stainless and nichrome components is designed to prevent negative impacts of vibrations of a strength far in excess of what we'd observe when it comes to using the woodscents.There is no way nichel-chromium alloy can be safe in air path, even if covered with steel, the particulate matter from the nichome would escape from any openings it sees in the sheathing.

The manufacturer in question (Not Ed) designed this sheathe explicitly for the purpose of preventing oxidation/corrosion from the surrounding atmosphere (this means that the sheathe needs to prevent air from getting inside of the sheathe - air as you know, is rather more able to squeeze through the tightest of spaces than even volatilized particulates from nickel-chromium). If there were an opening in the sheathing, it would seem that this would utterly defeat that explicit purpose of the design of the component and would serve as quite the indictment of the manufacturer! I've seen no evidence to suggest that such a failure would take place, or ever has taken place.

@7heLameGuy In order to substantiate the initial cause of your concern, I need to ask: What makes you think that the stainless steel will have an 'opening' which exposes the nichrome within? Have you seen some evidence that made you concerned that this would happen?

I have at present seen nothing to suggest that such an opening, exposing the nichrome to the vapor path is present, neither in the pics from Ed, nor in the materials that I've seen from the component manufacturer?!

I do apologize, I don't have time to look at the new wiring in the bottom of the woodscents that Ed has shared as of yet due to pressing IRL engagements, however, I'll return once I get the chance to speak to this

|

Sponsored by |

|---|

|

|

|