herbivore21

Well-Known Member

****This safety review pertains to WoodScents cores made prior to October 2019.****

Whilst I have never received anything for free from Ed and generally do not buy wooden vape products, my experience with him as a customer in the past was wonderful.

Long (probably years now!) ago, Ed, a fellow member of a certain online community told me about his plans to develop a log vaporizer. Life got in the way of this plan for a while and it would still be some time before he brought a vape to market. In the meantime, he has always been somebody that I've been happy to shoot the shit with about vaping.

Fast forward to now and you guys can imagine how excited I am to journey through the paces with Ed as we look into the safety of his new vaporizer design.

So without further ado, let's journey down the rabbit hole:

@Ed's TnT Thanks so much for your eager participation too, we've not put many units through the paces and we do now have our VA Safety Approvals process in place (thanks as always to @momofthegoons !), so I will provide some information from the guidelines from which to derive some initial questions (which are a good starting point even if you do not seek a VA Safety Approval - which is voluntary):

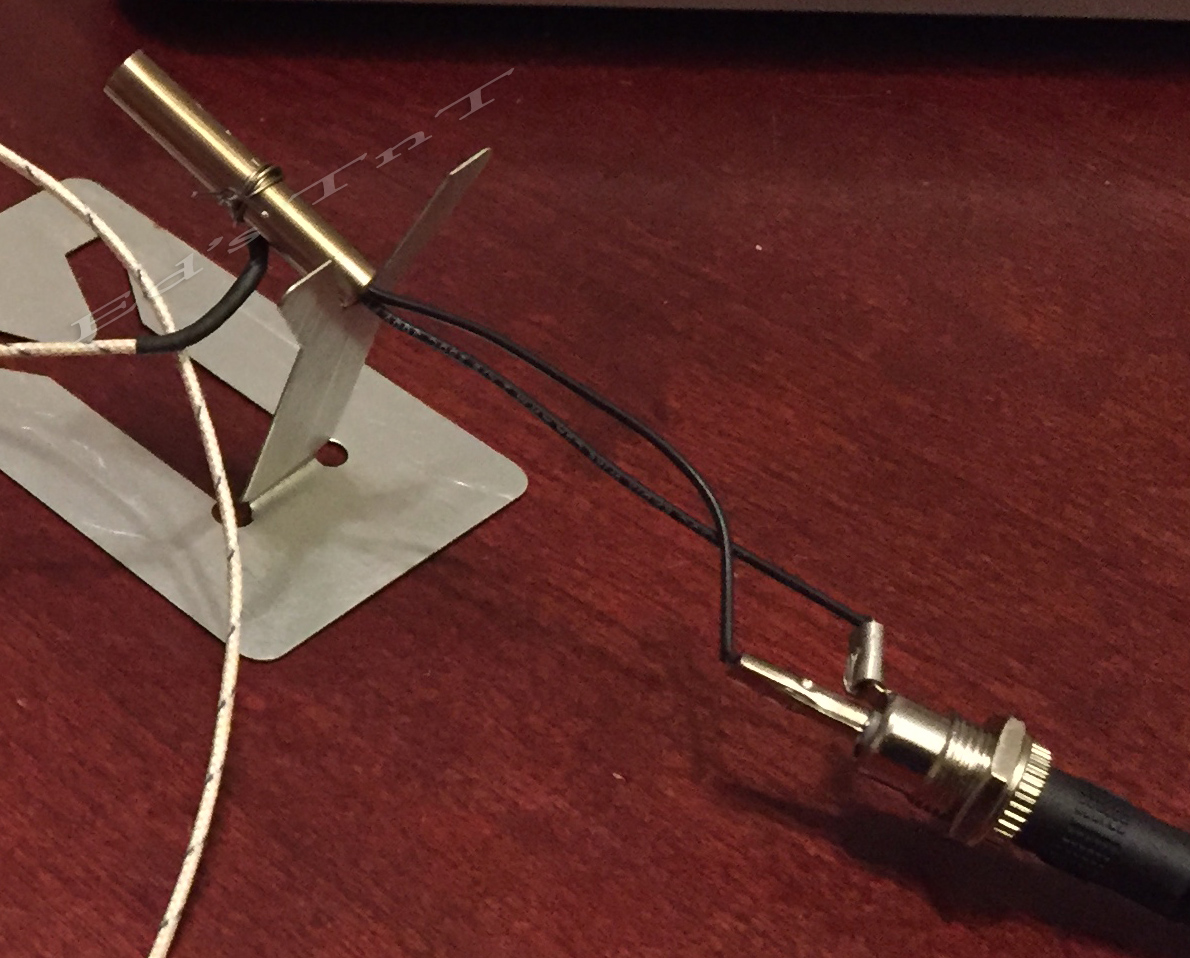

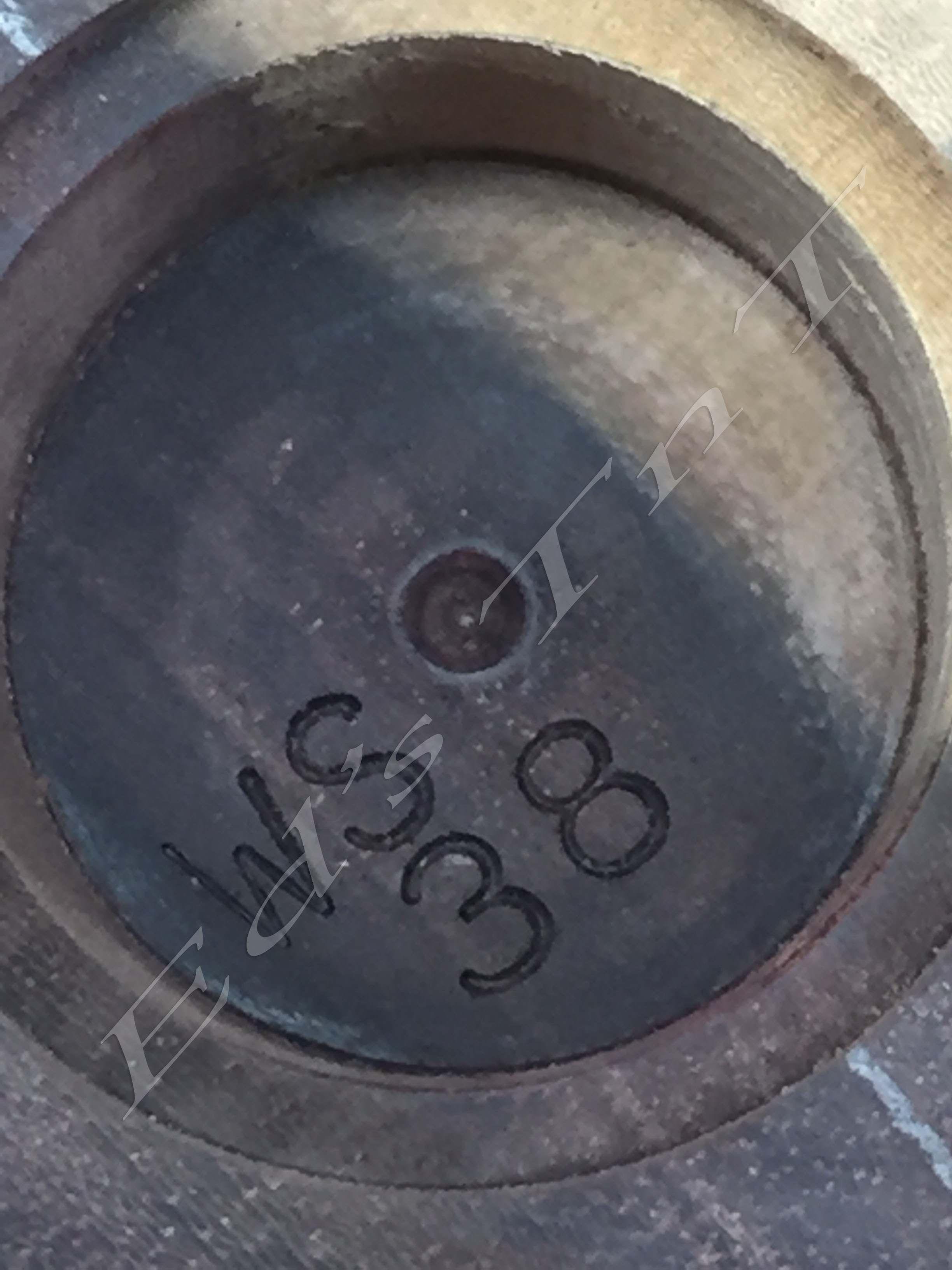

*ALL materials used in the device must be listed. Pictures or video of a teardown of the unit are required, clearly listing and identifying all components.

*The air and vapor path of the vaporizer must be described in detail, with the location of the air intake clearly identified and all components and materials described.

This raises the following questions:

1. Can we please have a list of all components in your Woodscents Vaporizer, including all of the relevant materials used?

2. Can you please provide teardown photos or video to indicate which components are which and provide a visual reference as to your design?

3. Can you please describe where the air is taken into the unit, as well as specify all of the above components that sit in the air/vapor path?

Please keep in mind that you may voluntarily seek a VA Safety Approval by meeting these criteria. Please do indicate if you wish to do so and we can carry on in this thread as such

With answers to these questions, we can let the safety discussion begin!

I thank @Ed's TnT once again for participation and look forward to participating in this one myself!

Whilst I have never received anything for free from Ed and generally do not buy wooden vape products, my experience with him as a customer in the past was wonderful.

Long (probably years now!) ago, Ed, a fellow member of a certain online community told me about his plans to develop a log vaporizer. Life got in the way of this plan for a while and it would still be some time before he brought a vape to market. In the meantime, he has always been somebody that I've been happy to shoot the shit with about vaping.

Fast forward to now and you guys can imagine how excited I am to journey through the paces with Ed as we look into the safety of his new vaporizer design.

So without further ado, let's journey down the rabbit hole:

@Ed's TnT Thanks so much for your eager participation too, we've not put many units through the paces and we do now have our VA Safety Approvals process in place (thanks as always to @momofthegoons !), so I will provide some information from the guidelines from which to derive some initial questions (which are a good starting point even if you do not seek a VA Safety Approval - which is voluntary):

*ALL materials used in the device must be listed. Pictures or video of a teardown of the unit are required, clearly listing and identifying all components.

*The air and vapor path of the vaporizer must be described in detail, with the location of the air intake clearly identified and all components and materials described.

This raises the following questions:

1. Can we please have a list of all components in your Woodscents Vaporizer, including all of the relevant materials used?

2. Can you please provide teardown photos or video to indicate which components are which and provide a visual reference as to your design?

3. Can you please describe where the air is taken into the unit, as well as specify all of the above components that sit in the air/vapor path?

Please keep in mind that you may voluntarily seek a VA Safety Approval by meeting these criteria. Please do indicate if you wish to do so and we can carry on in this thread as such

With answers to these questions, we can let the safety discussion begin!

I thank @Ed's TnT once again for participation and look forward to participating in this one myself!

Last edited by a moderator:

I am personally glad to hear that you take such care to select safe wood from sources who do right by their workers and the environment. I am sure others here appreciate this too

I am personally glad to hear that you take such care to select safe wood from sources who do right by their workers and the environment. I am sure others here appreciate this too

).

).