My first main question is... how much pressure can I exert with a decent record vice, a scaffold pole, and some anger....???

You should be able to get ~2000 pounds of pressure into your vise in this way brother, perhaps more depending on the vise in question and how much of that day's newspaper you've read that morning

As my friend

@Hogni says, sadly our buddy Joel doesn't make plates anymore due to changes in his own circumstances. A shame, he's a stand up guy and his products have stood the test of time IME.

Shame about the lack of availability for them plates.. Ill may make my own..

And I can't wait months, iv waited my whole life already....

I understand the relationship between force and suface area... so preferably I want as small as I can get away with...

With the vice method I could use a torque wrench to gauge my pressure as a reference point... But I image is just want as much as possible...

Cant have too much pressure right...???

Basically speaking, you're right here. A 1 ton vise used to press will allow you to press between .3-1g at a time. The lower end of this range should extract almost all, if not all of the rosin in one press. The bigger sized amounts of flower I mention will require 2 or 3 presses.

More pressure and bigger plates means you can press more at a time, within limits.

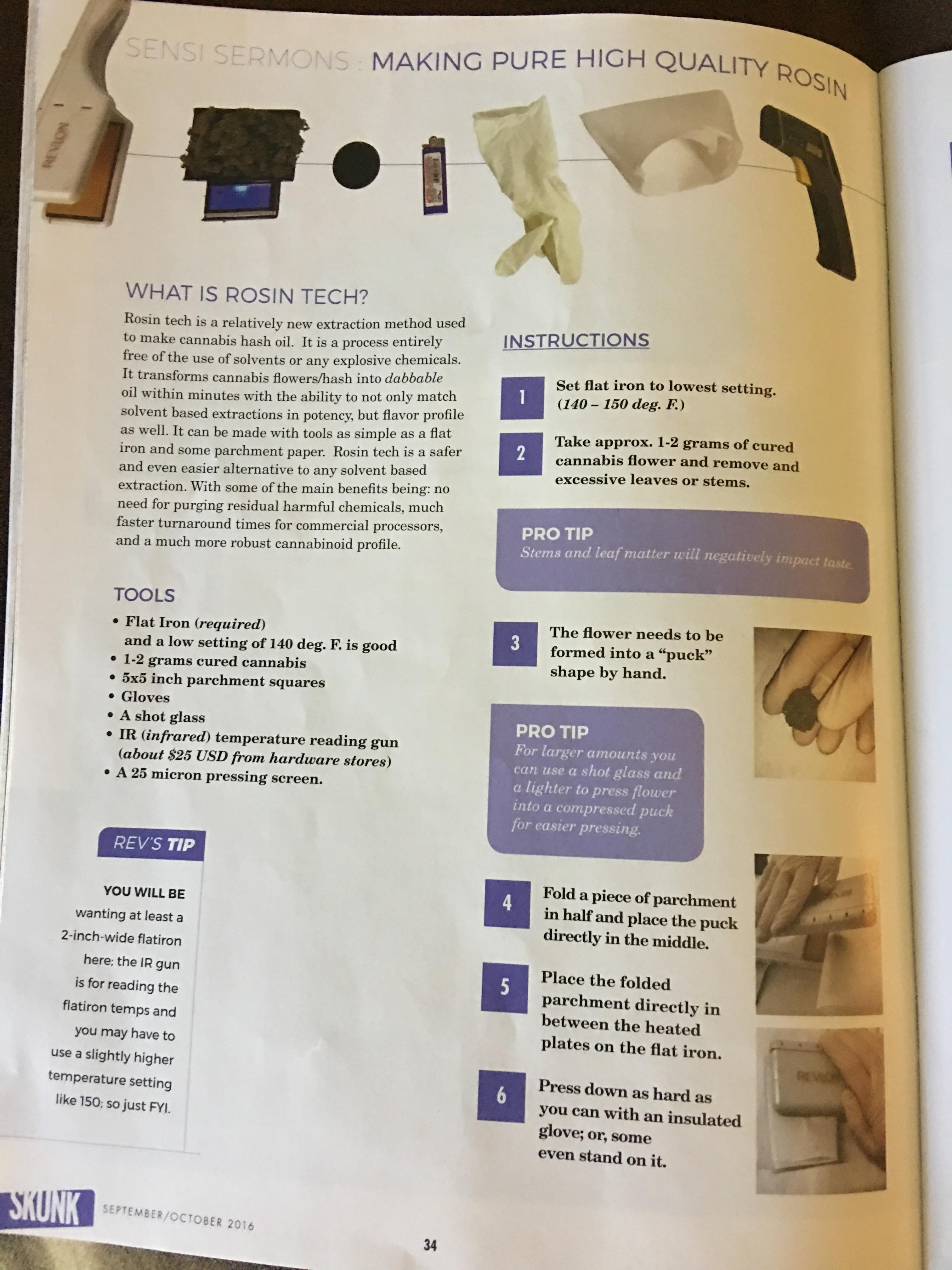

Last night I squished with straighteners again, This time I had them on the lowest setting and switched them off 30 secs before squish...

(Scientifically accurate I know, but I'm just playing right now..)

Anyway I got far better results this time, more glassy, and far more tasty....

But took far more effort....

The colour stays the same though, maybe this is more to do with the age of my herbs used..

Fresher = more light goldern...???

Excellent work man, it is amazing how good the results can be even when using a straightener in this way isn't it?! I started out pressing with a straightener and vise personally also :)

You are right, cured flower will give you darker rosin, but often, the darker rosin from cured flower tastes better than rosin from fresher flower. It will depend on the chemovar you are working with as to whether this is the case or not.

I had to really fucking squish with all my effort to get this... im at my limits of man power now...

Cant work out if my hand squeeze is more or less powerful, than my body weight....

Anyway im having much fun with this... should have done it ages ago, rather than piss about with solvents, waiting times, and purging...

Cant wait to get my squish rig built...

I have you

@herbivore21 to thank for this....

Thanks mate.....

It is my great pleasure, my friend. It is reward enough for me to know that you're getting delicious solventless meds out of those wonderful flowers that you've worked so hard to have

My friends

@momofthegoons and

@Killick had a great idea suggesting using a dimmer to reduce the stable temp while the straightener is on

My very limited squishing knowledge would make me think that maybe you are using too much heat, and not enough squish...???

This is a good guess.

@momofthegoons it is often the case that we use more heat and less pressure when manually trying to press nugs, since putting enough force on a straightener using our body weight alone to get good yields at lower temps is very challenging. The temp ranges I suggest above alongside those pressure measures should give you an idea of what we need. A clamp or vise can help get the requisite pressure, but of course, may also break the straightener. I've broken many myself in the past lol

There's no doubt the temp was too high. I was impatient and couldn't wait any longer. I'll be a bit more thorough next time.

I squished for about 15 - 20 seconds so I think the time was long enough. I'm thinking the temp was the problem?

Mine also came off the paper easily. I was sort of surprised because I've tried this before and it was sticky/wet and didn't come off easily until a couple days later; like there was moisture in the rosin.

But the flavor suffered a bit. I dabbed it and it was a bit harsh. Not like other rosin I've had from the same method. So that sort of solidified that I had squished at too high a temp.

But fun stuff!

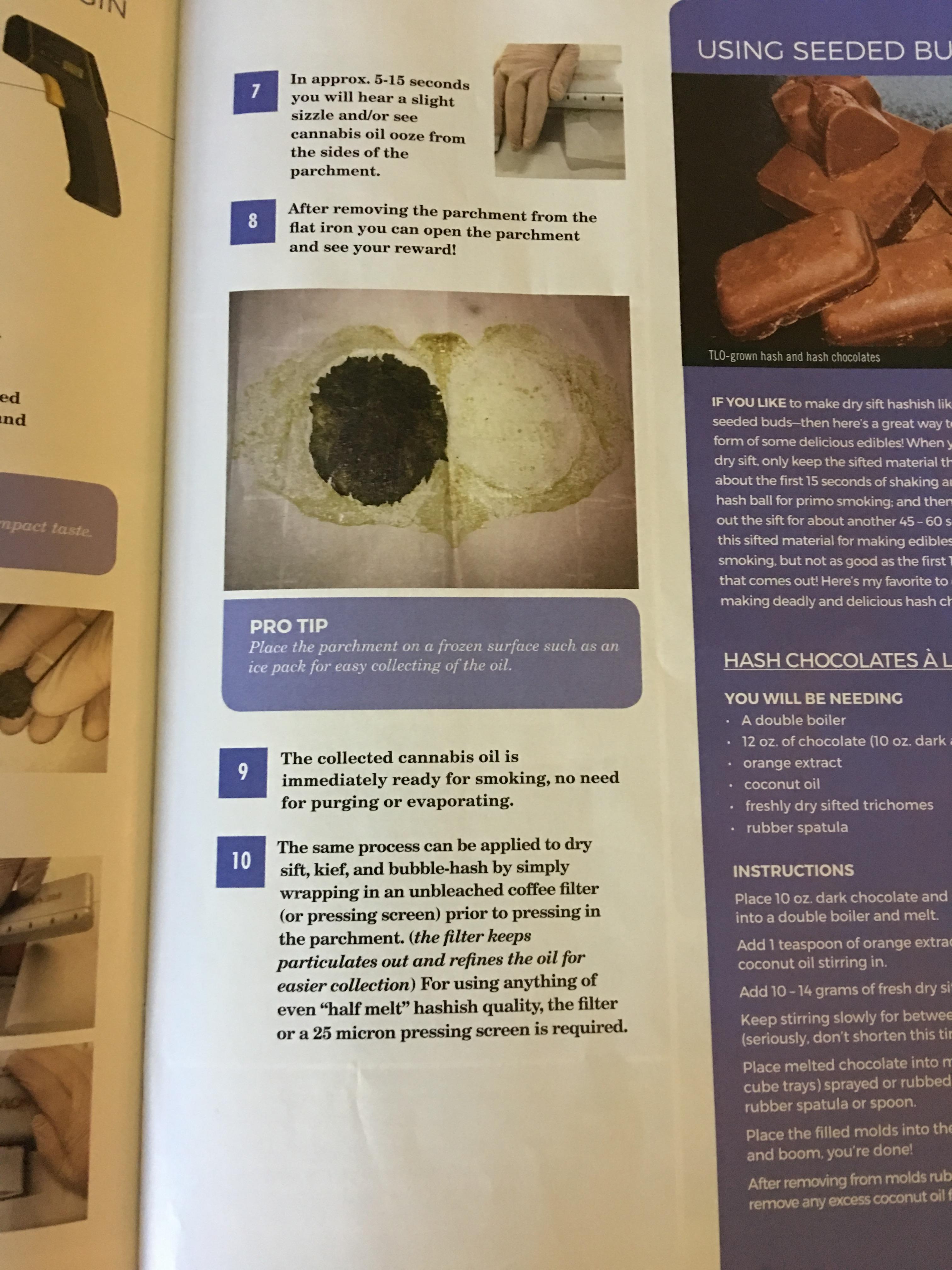

Placing your collection on a cold surface can make it easier to remove from the parchment :)

We need to discuss parchment options more broadly too. I should say that I only recommend using a small handful of products made by Oil Slick for pressing. I have used RAW and the usual suspects for cooking parchment, as well as all of the Oil Slick offerings (not the new clear one).

In the past, the old style Oil Slick Slick Wrap product was great for rosin, the new version (with hydroguard, look for the large blue sticker on the box) is not safe to use with rosin, as a plastic layer was added to the product to protect meds stored inside it in high humidity environments (humidity could cause the parchment layer to delaminate into your meds). Now, the best Oil Slick product for pressing rosin is what they call Oil Slick 'Slick Paper'. Collecting rosin from this Slick Paper (as well as the old 'Slick Wrap' that was safe for pressing) is much easier than the other parchments out there, these really are the ultimate and I would never even countenance pressing without the respective Oil Slick parchment of my choice.

I use Oil Slicks' PTFE Slick Sheet for pressing rosin from hash (although I almost never press rosin from hash, as all of my hash is already dabbable and the rosin simply tastes inferior). I do not recommend PTFE for pressing nugs since deformation of the PTFE during the press could be a contamination risk. Nugs have a lot more pointy bits and require more pressure to rosin than hash does.

So what's the deal with the presquish...???

I presquish a little to just make it neat and keep it all together better..

Should I be proper squishing it to a flat..???

Also apparently a little heat first, without the squish, helps gett the juices flowing for a better yield on the squish...

Kind of like a primer draw on a conduction vape I suppose...

Anyway I'm having much fun with the squishing, and even more with the testing...

Im using very low temps and a long hard squish....

I can touch my plates without instant burns...

Pre-squishing can minimize the stress on your parchment imparted during the press that can cause blow-outs, also very important if you use screens to press.

Pre-squishing can also allow you to press larger amounts at a time and achieve better yields without your material ending up outside the plates.

I tend to squish very small amounts that I gently ball together in my hand, but with larger amounts, more diligent pre-squishing is important. When you are pressing very large amounts on a press larger than a vise, you really need to pre-squish your material to get it all to fit nicely.

Was there a link iv missed somewhere???

My rosin does look a little darker than id like to see, but this is due to me using 8 month old, well cured og kush....

Can't wait to see what fresher does....

I actually have some 2 year old kush, and some 3 year amnesia I may try...

But iv read that fresher is better....

When I next harvest I will set aside 4oz to squish....

That gives me a couple months to sort a squish rig out....

Don't worry about the darkness or lightness of your rosin. If your flower is cured, that darker rosin could be better than lighter rosin. I assure you, I've had full melt from long cured flower that looks as dark as some people's reclaim that tastes better than any pale oil I've ever dabbed.

Cured resin is IMO the reason why dark oil should not be dismissed out of hand. I prefer cured resin 90% of the time.

I look forward to seeing what you end up getting for a rig!

In thinking of buying this instead of making my rig.....

https://vapefiend.co.uk/pressie-heat-press

It can go as low as room temp and can achieve

1500psi..

@herbivore21 what you think...????

That press will allow you to do single nug presses similarly to what a vise press would allow. It is difficult to know how much pressure it can bring to bear on your nugs, since they only give a PSI measurement, and it is not clear whether they measured that by multiplying the total pressure able to be applied by the pneumatic press by the surface area of the plates, or of some hypothetical nug (PSI MUST BE MEASURED 'AT THE WORK', what I mean is that the plate surface area is not what you need to know to determine your PSI, rather, you need to use the surface area of your pre-squished nug).

Regardless, I would not expect that unit to allow presses beyond 1g at a time or so. A DIY vise press will achieve the same and a hydraulic press design with ready to order plates will far surpass what this one can do in terms of quantity. It depends on how much you want to press at a time really, if you want something ready made that can press up to 1g of flower at a time, this should work well :)