|

Sponsored by |

|---|

|

|

|

-

Need help navigating the forum? Find out how to use our features here.

-

Did you know we have lots of smilies for you to use?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Extraction Dabpress Rosin Plates

- Thread starter psychonaut

- Start date

As your pump tops out at 9000 psi, I thought this may match the kit I linked;

https://www.ebay.com.au/itm/2-4-60MM-Hydraulic-Pressure-Gauge-Meter-700KG-10000psi-Hot-sale/232155630342?_trkparms=aid=555018&algo=PL.SIM&ao=1&asc=52946&meid=cca8f9c345494d2f94cc99527f927c1a&pid=100005&rk=1&rkt=1&sd=263791389946&itm=232155630342&_trksid=p2047675.c100005.m1851

https://www.ebay.com.au/itm/10TON-PORTA-POWER-KIT-REPLACEMENT-HYDRAULIC-RAM-PUMP-HOSE-ONLY-BODY-REPAIR-KIT/251616730509?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2060353.m1438.l2649ump

The pump can be purchased without the rams etc,

https://www.ebay.com.au/itm/2-4-60MM-Hydraulic-Pressure-Gauge-Meter-700KG-10000psi-Hot-sale/232155630342?_trkparms=aid=555018&algo=PL.SIM&ao=1&asc=52946&meid=cca8f9c345494d2f94cc99527f927c1a&pid=100005&rk=1&rkt=1&sd=263791389946&itm=232155630342&_trksid=p2047675.c100005.m1851

https://www.ebay.com.au/itm/10TON-PORTA-POWER-KIT-REPLACEMENT-HYDRAULIC-RAM-PUMP-HOSE-ONLY-BODY-REPAIR-KIT/251616730509?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2060353.m1438.l2649ump

The pump can be purchased without the rams etc,

Last edited:

Nice find @LesPlenty I wonder if that seller in China has an adapter for that gauge that can go in line on the hose between it and the pump?

felvapes

Well-Known Member

That is an affordable pump. I continue to search for a 1/4" NPT male -> 1/4" NPT female gauge adapter to place inline between the pump and hose, so far I am only finding 3/8" size which is the more common (also expensive?) NPT threading for hydraulics.

I'm getting closer I think. Legos come to mind. Here is a T adapter, perhaps with the right fittings to change the male parts to female, this could work, or at least be on a trail towards a gauge adapter that'll work.

I found some 1/4" gauge tee port adapters but they only had a max working rating of 5000 PSI, this one is 10000 PSI but all ends the same. I think they have other parts that could convert male>female or female>male.

http://www.impactimpex.com/hpteemale.html

http://www.impactimpex.com/hpteefemalexfemale.html

I'm getting closer I think. Legos come to mind. Here is a T adapter, perhaps with the right fittings to change the male parts to female, this could work, or at least be on a trail towards a gauge adapter that'll work.

I found some 1/4" gauge tee port adapters but they only had a max working rating of 5000 PSI, this one is 10000 PSI but all ends the same. I think they have other parts that could convert male>female or female>male.

http://www.impactimpex.com/hpteemale.html

http://www.impactimpex.com/hpteefemalexfemale.html

Last edited:

felvapes

Well-Known Member

In the exact same boat...lolI found the same problems, most are 3000-5000psi, a trip to the local Enzed dealer would likely be a fix(or Blackwoods) If I hadn't just blown all my vape money on a new Tera and Mighty I might have taken the plunge, time for some saving and researching.

Bloody VAS/GAS and sales....lol

This is looking the path though for the near future.....

My mate sold his Enzed truck and franchise dammit or would be able to get what we need el cheapo

Mind you I have a mate who cuts and moulds metal pieces

Might see what he can do

Happy Saturday Asylum members!

We've extended the 10% off coupon code DABPRESS-10 to help save rosineers money for the holiday season. I dunno how long this coupon code will be running so enjoy the extra savings while they last!

The strongway pump at Northern Tool and Equipment is still backordered online 3-8 days though you should still be able to get your press setup before the holidays! Seems there was a run on pumps

We've extended the 10% off coupon code DABPRESS-10 to help save rosineers money for the holiday season. I dunno how long this coupon code will be running so enjoy the extra savings while they last!

The strongway pump at Northern Tool and Equipment is still backordered online 3-8 days though you should still be able to get your press setup before the holidays! Seems there was a run on pumps

bizwaxzion

Enigmatic Cannabist

Want to start with a huge thank you to Roger (@dabpress.com) and @psychonaut for bringing these presses to market and for the outstanding customer care. My questions where answered promptly and honestly and the entire purchase was quick and smooth. Got the 10T driptech press setup last night for it's maiden voyage and ran a 4g puck of some sour tangie. Had a couple friends over - noobz to the rosin/dab scene - and they were blown away. I was too excited and forgot to collect and weigh the result until we had dabbed away over half of it in one of Shane's (@710 coils) bangers, but I estimate around 0.7g. I pressed for about 3.5m @195F.

Want to start with a huge thank you to Roger (@dabpress.com) and @psychonaut for bringing these presses to market and for the outstanding customer care. My questions where answered promptly and honestly and the entire purchase was quick and smooth. Got the 10T driptech press setup last night for it's maiden voyage and ran a 4g puck of some sour tangie. Had a couple friends over - noobz to the rosin/dab scene - and they were blown away. I was too excited and forgot to collect and weigh the result until we had dabbed away over half of it in one of Shane's (@710 coils) bangers, but I estimate around 0.7g. I pressed for about 3.5m @195F.

Thank you @bizwaxzion really happy to hear your adventures are off to a great start! If you run a lot of smaller personal sized runs you may wanna look at the rosin filter sleeve tubes we offer. They are only 160u but they are 500mm in length and you can cut them to size. I think they end up being a little more convenient if you are using the 30mm pre-press mold, vs the 2x4" bags, might also get more use out of the nylon that way.

Rosin on quartz is really tasty, I am still not sure what I prefer more, I keep going back to the SiC halo since my quartz is all torch at the moment. The Halo just gives up the vapor like none other in my collection.

---------------

I did a lil squish today on some 7 week cured orange hill special 62% RH. 5g in 0.87g out, buds were not de-stemmed and was a combo of tops and larf. Quite happy with that yield, I know the colas are gonna be up there!

I just did a 30mm pre-press with 5g and used a 160u rosin filter tube cut to about 3", pressed the puck, close to the edge, tilted forward for drip tech and started to get a nice blob going and noticed that the rosin was buddering up right at the edge of the plates. The honeycomb eventually fell off but it was too late as it dammed up the flow! 200F on PID @ 3 mins 1700 PSI on strongway gauge (approx 1500 PSI on puck)

That's single layer kirkland parchment, real nice stuff, gonna go get more next week at costco

GreenHopper

20 going on 60

I made quite a few mistakes.

However this was my first press ever, I was in a hurry and I was not being careful in any way.

Errors I made:

The starting material was home grown Gorilla Glue #4 by fast buds (not the DHG genetics). It had been cured for about 7-8 months and was stored roughly around 62%. The RH went up when I popped the jar open.

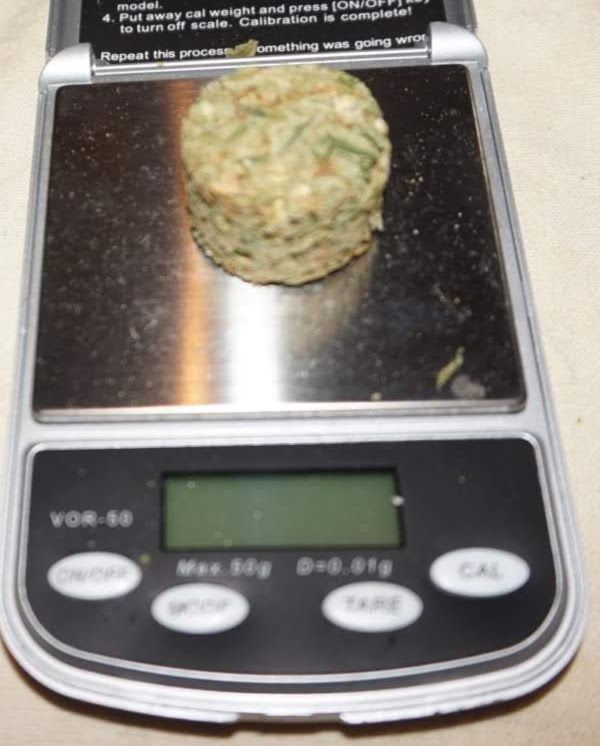

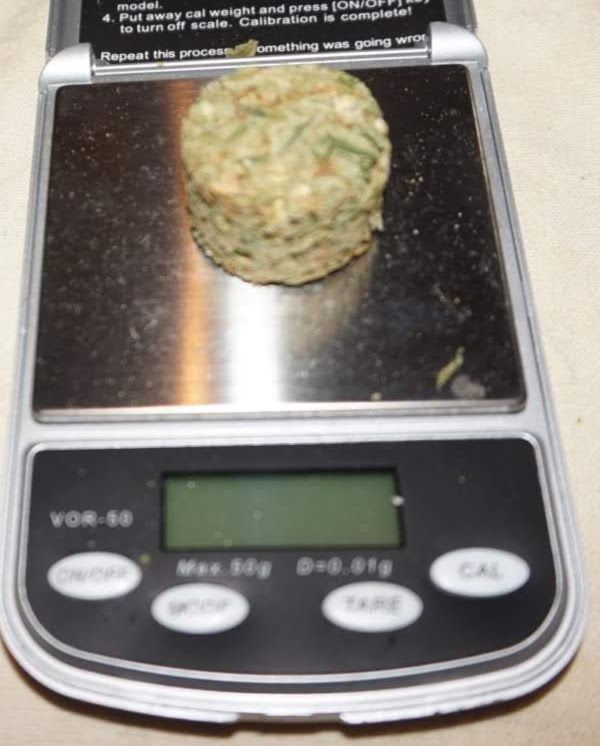

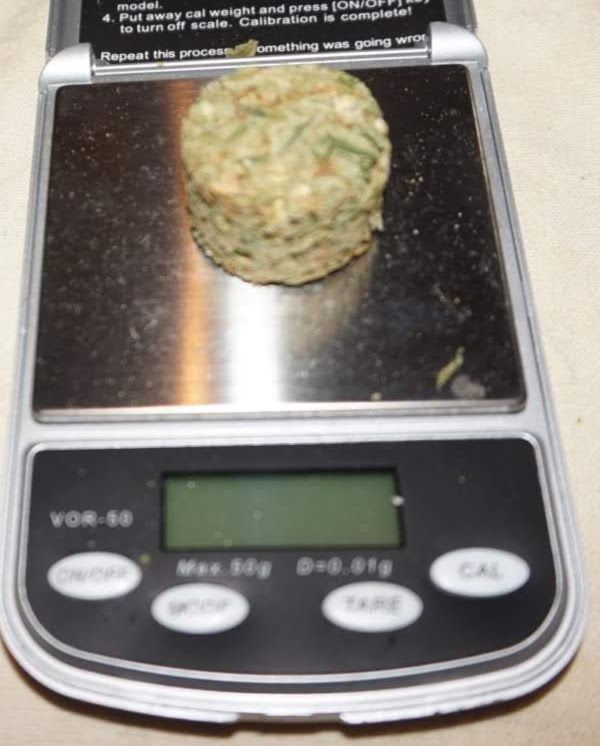

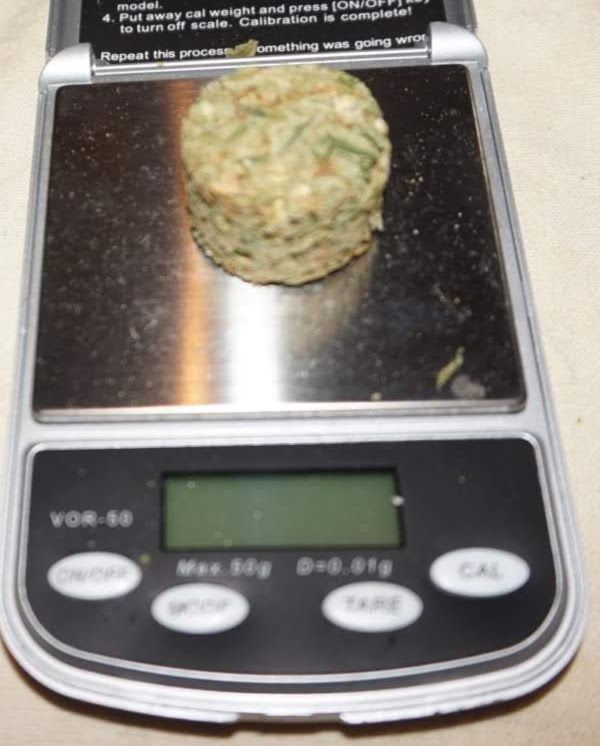

'Dabpress iBudtek dp-pm3015r CylinderPre-press Mould Made of Anodized Aluminium' was used to create the puck:

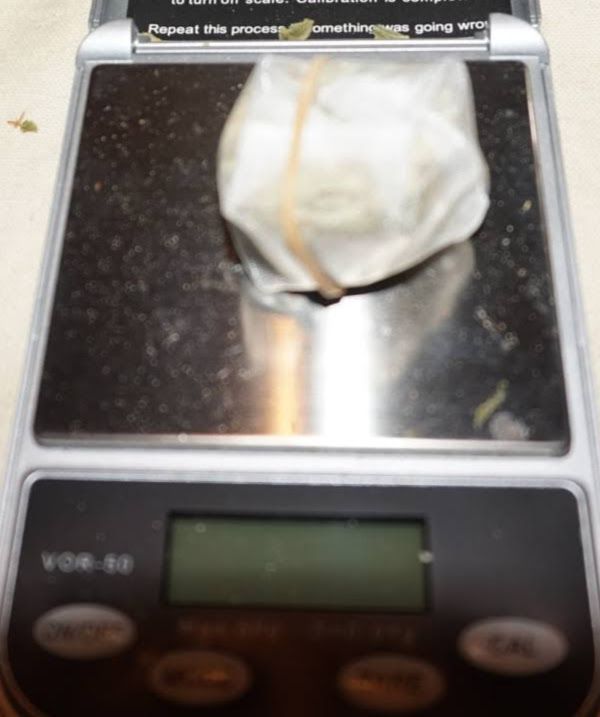

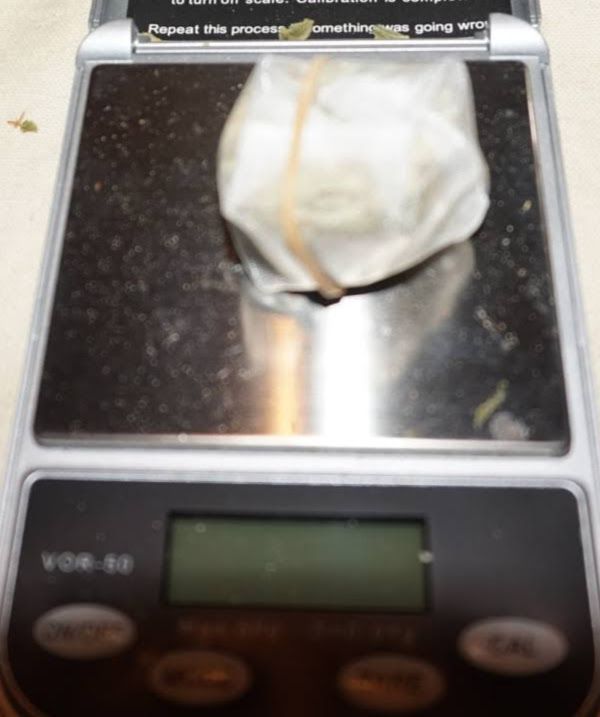

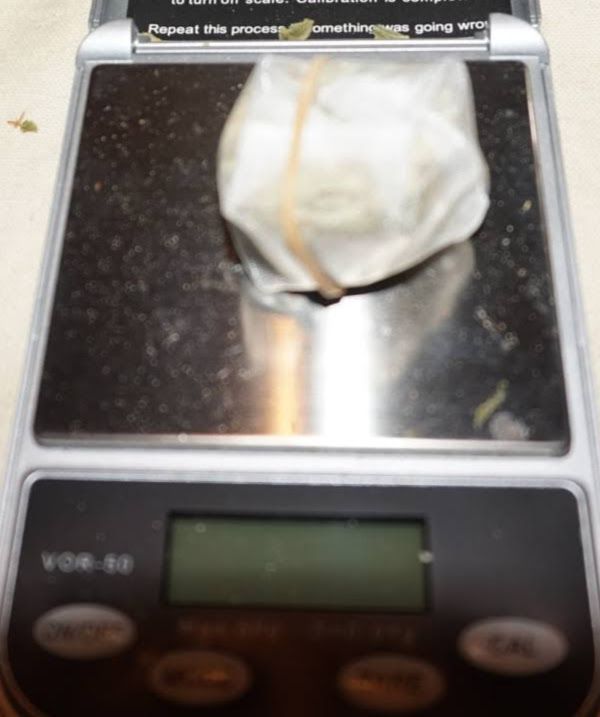

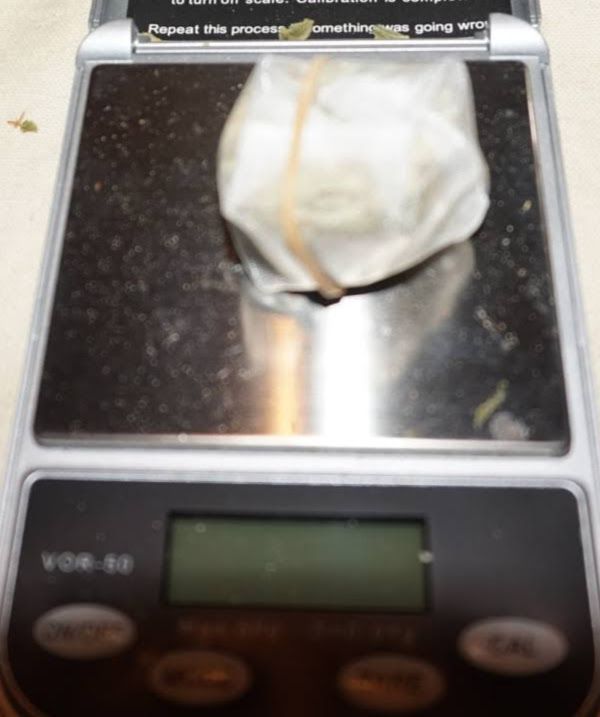

The puck fit perfectly into 'Dabpress iBudtek dp-bt160ns Stitched Extraction Filter Bag - 160 Micron Bags':

Damn scales powered down just as I was taking the pic but it was reading 3.60g

I set the temp on the PID's to 200 and pressed at about 5000PSI. I wasn't particularly smooth about applying the pressure so I'm not surprised by theblowout:

Despite the blowout the squish actually looks ok.

You can see I didn't use enough PTFE, Rosin flowed out on the left and so I lost some to the plates. This is all down to my technique, which is n00b level right now.

You can see the indentations in the PTFE sheet in this pic.

Blob of goo, this was quite brittle stuff actually, it did not flow that much and collecting it was fairly easy but the thinner bits were breaking up and pinging around a bit.

So what did we get:

Well, considering I went at this like a brute with zero experience and lost some rosin to the plates I'd say this is ok for my first ever run.

The puck was still gleaming as well so I suspect going slower and applying the pressure with more care would allow me to improve significantly on yields.

I have kept the puck and will do something like an ETH extraction when I have enough chips. Getting the chip out of the filter bag seems like trouble and a lot of the resin was on the bag so I'm keeping the filer bags on the chips.

This pic was supposed to show the Rosin still on the plates but I lost patience trying to work an angle where you could actually see the mess I made.

There is a bit of rosin on the front lip but there was also more further back.

I think the 'Dabpress dp-hr10t35v 10-Ton Hydraulic Cylinder Rosin Press' is a great Rosin Extraction device and I look forward to learning how to properly use it.

However this was my first press ever, I was in a hurry and I was not being careful in any way.

Errors I made:

- I cut the PTFE paper too small so goo got on the plates. Not too much but enough. It was hard to photo the rosin on the plates as the camera flash kept bleaching it out. I used an alcohol wipe to clean it all off.

- I used too much pressure, too quickly and blew the filter bag out. 5000 PSI is way too high for the 3.6g I was pressing.

- The rosin was very brittle, when collecting I could see small bits pinging off all over the place. I think I got most of it but some specks got away.

The starting material was home grown Gorilla Glue #4 by fast buds (not the DHG genetics). It had been cured for about 7-8 months and was stored roughly around 62%. The RH went up when I popped the jar open.

'Dabpress iBudtek dp-pm3015r CylinderPre-press Mould Made of Anodized Aluminium' was used to create the puck:

The puck fit perfectly into 'Dabpress iBudtek dp-bt160ns Stitched Extraction Filter Bag - 160 Micron Bags':

Damn scales powered down just as I was taking the pic but it was reading 3.60g

I set the temp on the PID's to 200 and pressed at about 5000PSI. I wasn't particularly smooth about applying the pressure so I'm not surprised by theblowout:

Despite the blowout the squish actually looks ok.

You can see I didn't use enough PTFE, Rosin flowed out on the left and so I lost some to the plates. This is all down to my technique, which is n00b level right now.

You can see the indentations in the PTFE sheet in this pic.

Blob of goo, this was quite brittle stuff actually, it did not flow that much and collecting it was fairly easy but the thinner bits were breaking up and pinging around a bit.

So what did we get:

Well, considering I went at this like a brute with zero experience and lost some rosin to the plates I'd say this is ok for my first ever run.

The puck was still gleaming as well so I suspect going slower and applying the pressure with more care would allow me to improve significantly on yields.

I have kept the puck and will do something like an ETH extraction when I have enough chips. Getting the chip out of the filter bag seems like trouble and a lot of the resin was on the bag so I'm keeping the filer bags on the chips.

This pic was supposed to show the Rosin still on the plates but I lost patience trying to work an angle where you could actually see the mess I made.

There is a bit of rosin on the front lip but there was also more further back.

I think the 'Dabpress dp-hr10t35v 10-Ton Hydraulic Cylinder Rosin Press' is a great Rosin Extraction device and I look forward to learning how to properly use it.

ataxian

In a BLACK HOLE!

U have a DAB PRESS?I made quite a few mistakes.

However this was my first press ever, I was in a hurry and I was not being careful in any way.

Errors I made:

Now on to the good bits:

- I cut the PTFE paper too small so goo got on the plates. Not too much but enough. It was hard to photo the rosin on the plates as the camera flash kept bleaching it out. I used an alcohol wipe to clean it all off.

- I used too much pressure, too quickly and blew the filter bag out. 5000 PSI is way too high for the 3.6g I was pressing.

- The rosin was very brittle, when collecting I could see small bits pinging off all over the place. I think I got most of it but some specks got away.

The starting material was home grown Gorilla Glue #4 by fast buds (not the DHG genetics). It had been cured for about 7-8 months and was stored roughly around 62%. The RH went up when I popped the jar open.

'Dabpress iBudtek dp-pm3015r CylinderPre-press Mould Made of Anodized Aluminium' was used to create the puck:

The puck fit perfectly into 'Dabpress iBudtek dp-bt160ns Stitched Extraction Filter Bag - 160 Micron Bags':

Damn scales powered down just as I was taking the pic but it was reading 3.60g

I set the temp on the PID's to 200 and pressed at about 5000PSI. I wasn't particularly smooth about applying the pressure so I'm not surprised by theblowout:

Despite the blowout the squish actually looks ok.

You can see I didn't use enough PTFE, Rosin flowed out on the left and so I lost some to the plates. This is all down to my technique, which is n00b level right now.

You can see the indentations in the PTFE sheet in this pic.

Blob of goo, this was quite brittle stuff actually, it did not flow that much and collecting it was fairly easy but the thinner bits were breaking up and pinging around a bit.

So what did we get:

Well, considering I went at this like a brute with zero experience and lost some rosin to the plates I'd say this is ok for my first ever run.

The puck was still gleaming as well so I suspect going slower and applying the pressure with more care would allow me to improve significantly on yields.

I have kept the puck and will do something like an ETH extraction when I have enough chips. Getting the chip out of the filter bag seems like trouble and a lot of the resin was on the bag so I'm keeping the filer bags on the chips.

This pic was supposed to show the Rosin still on the plates but I lost patience trying to work an angle where you could actually see the mess I made.

There is a bit of rosin on the front lip but there was also more further back.

I think the 'Dabpress dp-hr10t35v 10-Ton Hydraulic Cylinder Rosin Press' is a great Rosin Extraction device and I look forward to learning how to properly use it.

Will U go 2 FRANCE and MEDICATE with me?

felvapes

Well-Known Member

Great post mate cheersI made quite a few mistakes.

However this was my first press ever, I was in a hurry and I was not being careful in any way.

Errors I made:

Now on to the good bits:

- I cut the PTFE paper too small so goo got on the plates. Not too much but enough. It was hard to photo the rosin on the plates as the camera flash kept bleaching it out. I used an alcohol wipe to clean it all off.

- I used too much pressure, too quickly and blew the filter bag out. 5000 PSI is way too high for the 3.6g I was pressing.

- The rosin was very brittle, when collecting I could see small bits pinging off all over the place. I think I got most of it but some specks got away.

The starting material was home grown Gorilla Glue #4 by fast buds (not the DHG genetics). It had been cured for about 7-8 months and was stored roughly around 62%. The RH went up when I popped the jar open.

'Dabpress iBudtek dp-pm3015r CylinderPre-press Mould Made of Anodized Aluminium' was used to create the puck:

The puck fit perfectly into 'Dabpress iBudtek dp-bt160ns Stitched Extraction Filter Bag - 160 Micron Bags':

Damn scales powered down just as I was taking the pic but it was reading 3.60g

I set the temp on the PID's to 200 and pressed at about 5000PSI. I wasn't particularly smooth about applying the pressure so I'm not surprised by theblowout:

Despite the blowout the squish actually looks ok.

You can see I didn't use enough PTFE, Rosin flowed out on the left and so I lost some to the plates. This is all down to my technique, which is n00b level right now.

You can see the indentations in the PTFE sheet in this pic.

Blob of goo, this was quite brittle stuff actually, it did not flow that much and collecting it was fairly easy but the thinner bits were breaking up and pinging around a bit.

So what did we get:

Well, considering I went at this like a brute with zero experience and lost some rosin to the plates I'd say this is ok for my first ever run.

The puck was still gleaming as well so I suspect going slower and applying the pressure with more care would allow me to improve significantly on yields.

I have kept the puck and will do something like an ETH extraction when I have enough chips. Getting the chip out of the filter bag seems like trouble and a lot of the resin was on the bag so I'm keeping the filer bags on the chips.

This pic was supposed to show the Rosin still on the plates but I lost patience trying to work an angle where you could actually see the mess I made.

There is a bit of rosin on the front lip but there was also more further back.

I think the 'Dabpress dp-hr10t35v 10-Ton Hydraulic Cylinder Rosin Press' is a great Rosin Extraction device and I look forward to learning how to properly use it.

Good results considering everything too

Makes me like the look of the dabpress products more so

For the DIY rosin press builder, harbor freight is having a sale on their 20-ton floor standing shop press for $140. There is also a 20% off super coupon, can't combine but can put towards a lower tonnage press that's not on sale if you wanna build a smaller press like 12-ton with dp-rp35s.

Paired with dp-rp37 caged cube kit (on sale now for $345 on Amazon) you'll have a 20-ton rosin press for under $500.

Paired with dp-rp37 caged cube kit (on sale now for $345 on Amazon) you'll have a 20-ton rosin press for under $500.

GreenHopper

20 going on 60

U have a DAB PRESS?

Will U go 2 FRANCE and MEDICATE with me?

I do indeed

Dab press = heavy (seriously heavy), you come here instead and medicate with me

Great post mate cheers

Good results considering everything too

Makes me like the look of the dabpress products more so

Thanks bud, I can confirm that the unit I have is very well made.

A solid unit indeed, the materials are high quality and everything feels like it was made with precision. Nothing rattles or feels loose, it's a heavy device but tips fairly easily for gravity induced drips.

The pump was easy to connect, the unit came with the Allen keys required for all the bolts. There was also a large-ish dab mat and a quick start guide 3-6 basic text / images.

I had to attach the 4x rubber feet using one of the Allen keys. That was easy enough, there was a spare foot and two spare fuses as well.

Lastly there was an alternative pump fitting and the IEC320C13 power cord to (in my case) UK plug.

Oh Yeh nearly forgot, there were also some magnets for holding open the parchment during a press.

ataxian

In a BLACK HOLE!

When I go to OXFORD UNION 4-sure.I do indeed

Dab press = heavy (seriously heavy), you come here instead and medicate with me

Thanks bud, I can confirm that the unit I have is very well made.

A solid unit indeed, the materials are high quality and everything feels like it was made with precision. Nothing rattles or feels loose, it's a heavy device but tips fairly easily for gravity induced drips.

The pump was easy to connect, the unit came with the Allen keys required for all the bolts. There was also a large-ish dab mat and a quick start guide 3-6 basic text / images.

I had to attach the 4x rubber feet using one of the Allen keys. That was easy enough, there was a spare foot and two spare fuses as well.

Lastly there was an alternative pump fitting and the IEC320C13 power cord to (in my case) UK plug.

Oh Yeh nearly forgot, there were also some magnets for holding open the parchment during a press.

Can One at least have a CBD pen in UK?

A DAB PRESS in South West FRANCE = CIVILIZED

GreenHopper

20 going on 60

When I go to OXFORD UNION 4-sure.

Can One at least have a CBD pen in UK?

A DAB PRESS in South West FRANCE = CIVILIZED

And you would be most welcome. PM me when you are about and we can figure out the rest

CBD Pens are good here in the yUK, you can buy them from vapefiend but they are currently out of stock. They also do crumbles and waxes.

Not the best news on the strongway pump procurement to pair with our hr10t35v rosin press. Seems the run on pumps has put northern tool & equipment stock on backorder 15-29 days!

I did find other pumps with gauges but they are not as affordable.

$199 - not positive if this is 1/4" NPT

http://ez-tools.us/Hydraulic-Hand-Pump-with-Pressure-Gauge-10-000-psi_2

$198 - 3/8" NPT fittings

https://www.prolinemax.com/MH3-Manu...mp-Pressure-Gauge-72-Hose-Coupler_p_2712.html

There are options for those who dont wanna wait, or can do without a gauge.

$44 -

https://www.ebay.com/itm/10-Ton-Hyd...=item3a8f8a5e1c:g:1CoAAOSwnlFaXntz:rk:31:pf:0

$50 -

https://www.ebay.com/itm/Porta-Powe...Ton-20-000lbs-Ram-Frame-Machine-/400801893452

I did find other pumps with gauges but they are not as affordable.

$199 - not positive if this is 1/4" NPT

http://ez-tools.us/Hydraulic-Hand-Pump-with-Pressure-Gauge-10-000-psi_2

$198 - 3/8" NPT fittings

https://www.prolinemax.com/MH3-Manu...mp-Pressure-Gauge-72-Hose-Coupler_p_2712.html

There are options for those who dont wanna wait, or can do without a gauge.

$44 -

https://www.ebay.com/itm/10-Ton-Hyd...=item3a8f8a5e1c:g:1CoAAOSwnlFaXntz:rk:31:pf:0

$50 -

https://www.ebay.com/itm/Porta-Powe...Ton-20-000lbs-Ram-Frame-Machine-/400801893452

Last edited:

Hey yall, Northern Tool and Equipment got back to me, they have 24 pumps in stock as of now online, with a lot more inventory coming by the end of December.

https://www.northerntool.com/shop/tools/product_200641798_200641798

https://smile.amazon.com/Strongway-Hydraulic-Pump-Gauge-Hose/dp/B00ULDGP2S

Rejoice

https://www.northerntool.com/shop/tools/product_200641798_200641798

https://smile.amazon.com/Strongway-Hydraulic-Pump-Gauge-Hose/dp/B00ULDGP2S

Rejoice

Aluminium Bling (half the weight for people on the go) and they ship to Australia.;

https://www.aliexpress.com/item/Man...lgo_pvid=776634c4-9f02-4d55-b759-e2f82d402fa5

I have purchased through Aliexpress before and they work like DHGate, they keep your money and only release it to the seller when you tell them you are happy.

https://www.aliexpress.com/item/Man...lgo_pvid=776634c4-9f02-4d55-b759-e2f82d402fa5

I have purchased through Aliexpress before and they work like DHGate, they keep your money and only release it to the seller when you tell them you are happy.

Last edited:

|

Sponsored by |

|---|

|

|

|