@GreenHopper

Looks great my friend! Thank you for the detailed squish!

I haven't used the PTFE sheets yet for pressing, but it almost looks like it indents a little more than parchment, maybe due to the thickness of the PTFE vs parchment? Thinking that may contribute to the oil not flowing out the front, if there's a micro-millimeter hump the oil has to get over to get out the front of the plates, it could barrier the oil some? Just a thought I had with no experience, just going by the photos. Also putting the puck about 1/3" in from the edge of the plates may help it flow out!

Your pressure is on the top end for the puck so I think you got most of the goodies out!

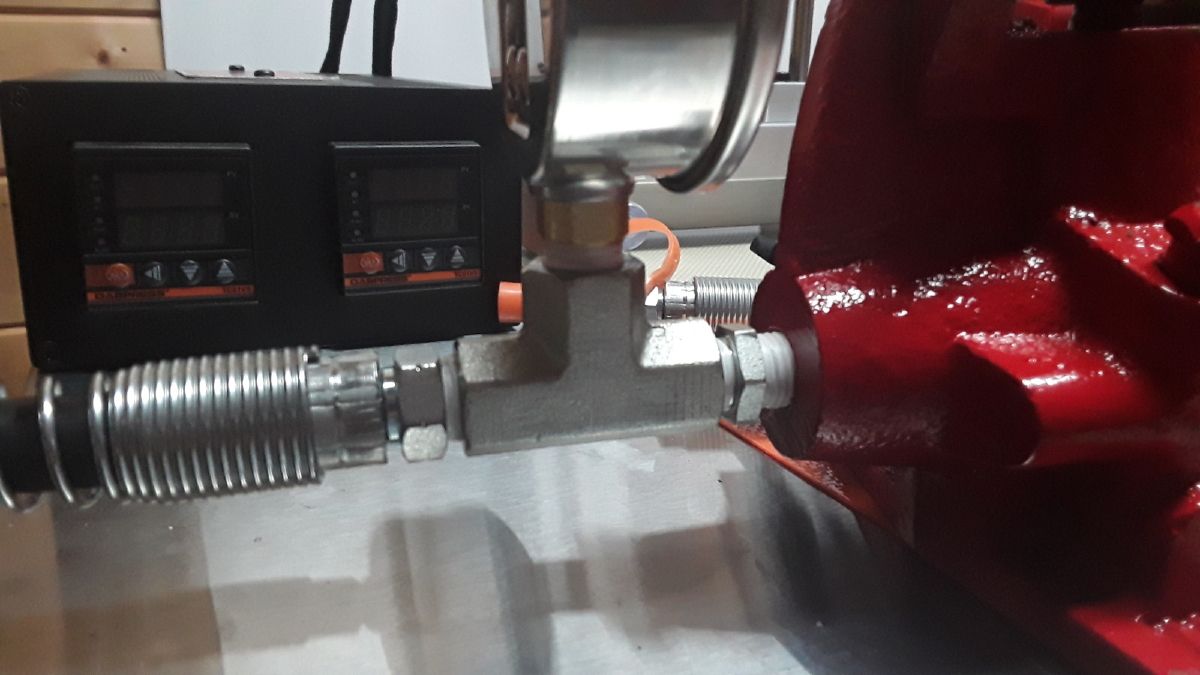

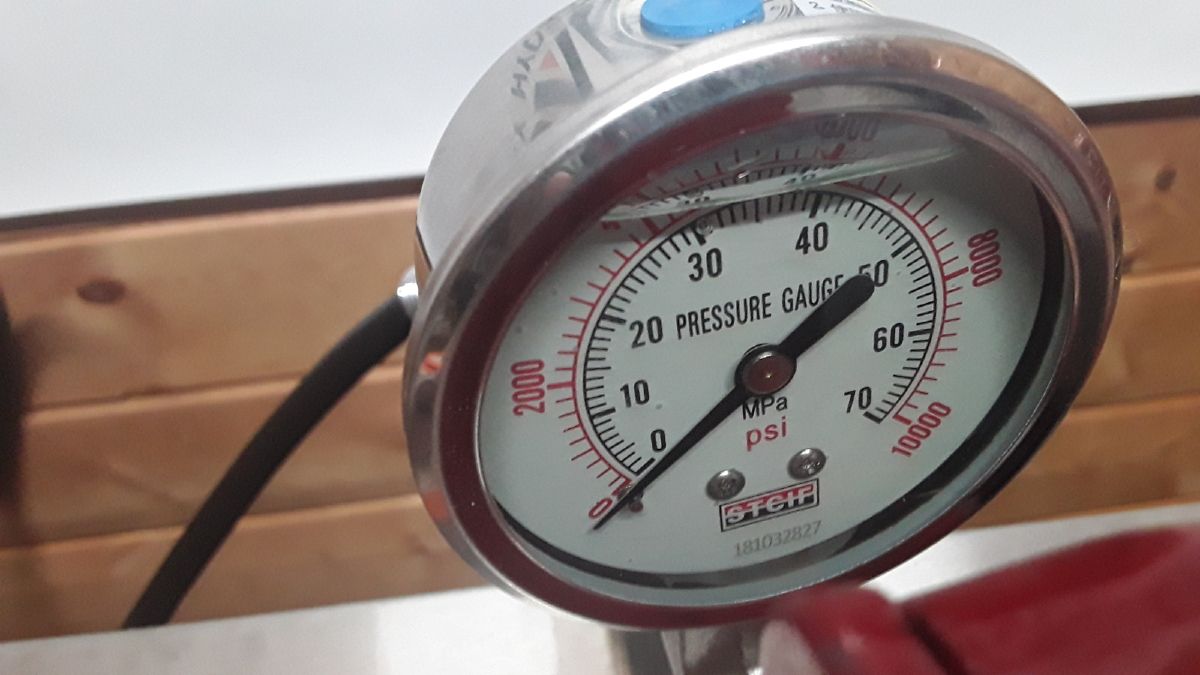

BTW, not sure if it was mentioned here but for calculating the PSI on the pucks with hr10t35v cylinder, I use this math -

PSI on gauge x 2.25 = total force applied

Total force applied / puck size in sq/in = PSI on the puck

2100 PSI on gauge x 2.25 = 4725 total force applied

4725 / (2" round finished puck diameter) 3.14 sq/in = ~1500 PSI on pressed puck.

I'd be curious to see what the yields are with 1000-1200 PSI on the puck with this same strain.