lolz-ya big fucking weed nerd!

Sooo? you going to answer the dudes question or you just going to assume he knows how much labor is in producing full melt bubble?

Some of us are barely literate, let alone have any clue as to how much effort is required to make dry sift or bubble.

Can ya pls dumb it down a bit for us heathens?

Or lemme guess? that is the dumbed down version?

So its a higher yielding technique you say?

Spill girlfriend........

I always found the quality of 27 star full melt bubble to be amazing, but the yields are an issue cause im a guts & it doesnt last. Sure ima baked of my ass and the flavours are totes amazeballs, but Id be going thru the equivalent of an oz every 2-3 days. that shit adds up quick.

However the prospect of better yields has piqued my interest.

lol this is a good question man! While I have discussed this stuff at another certain place on the internet, we haven't really covered the time/labor involved with bubble runs and dry sifting in the Asylum.

Bubble Hash Labor

Full melt bubble runs for me take roughly 8-12 hours of labor for the extraction and cleanup of equipment. Subsequent drying time of the bubble hash can vary widely, from hours (when freeze drying and other more 'assisted' drying methods) to days or longer (with traditional methods). Obviously, traditional drying methods are very hands-off while you simply wait for the material to sit and dry, and so this is more a time cost than labor.

For argument's sake, we might add 1-2 hours of hands on work for traditional drying (most of us don't have the money for a freeze dryer!) and then a few days to a few weeks of time involved waiting for the material to dry depending on a lot of factors.

Labor for my own method

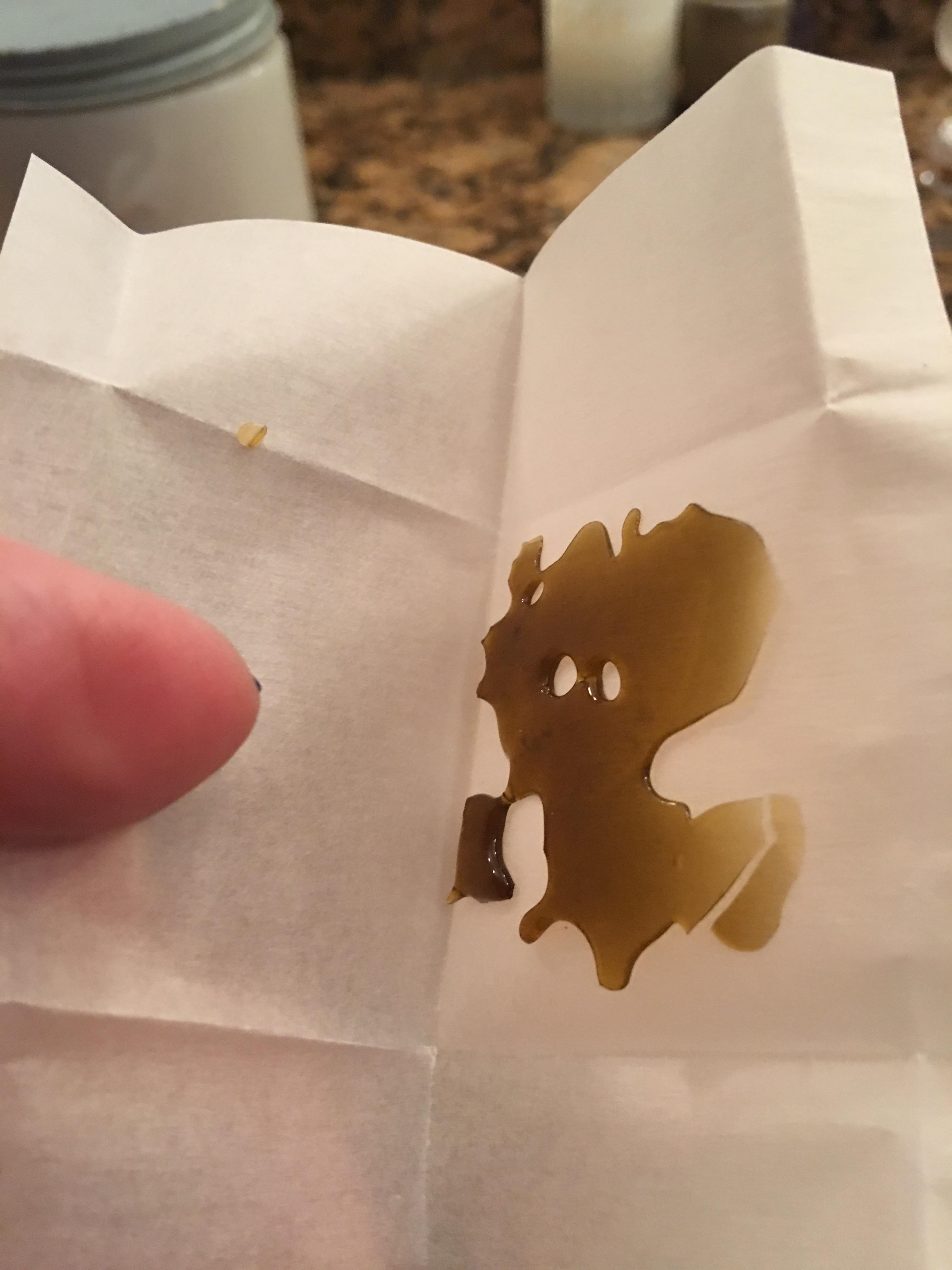

By comparison, the above pictured material that I made definitely requires a very similar amount of hands-on labor to full melt bubble above (approx 8-14 hours of hands-on work). None of the drying time though. It requires some equipment for processing that is not affordable or necessarily practical for most people's home use atm, however I have got some good ideas of how something more suitable and affordable for home users can be made in the future.

Full melt dry sift labor

Finally, making full melt dry sift is even longer and more hands-on work than bubble. It can take several entire waking days or more of labor to fully manually sift and clean up your product to full melt - it is a labor of love and honestly, I don't even have time to dedicate to this approach all the time. Full melt dry sift yields using traditional carding/static/screening methods are very low, similar to or less than full melt bubble runs (1-10% yields from flower depending on resin quantity in the flower).

Sometimes, a full melt dry sift gives a better representation of the original bud in the full melt that is made. Sometimes full melt bubble is better. This varies depending on the starting material, some chemical profiles lend themselves to one more than the other.

The processing method I am using gives returns more like rosin (15-30% yields depending again on the amount of resin).

For those like yourself who find they'll go through full melt etc too quickly to justify the cost and time, my abovementioned method and another one or two that I've been honing in recent times are likely to be more useful! Of course, there's more time at the drawing board required on my part before this will be something that others will be able to do themselves

I'd recommend folks who want to use tasty solventless concentrates rather than vaping flower in the meantime to use low temp flower rosin (190-200f @ 1000-2000 psi for flower) and grind/vape the rosin chips after in this scenario for now